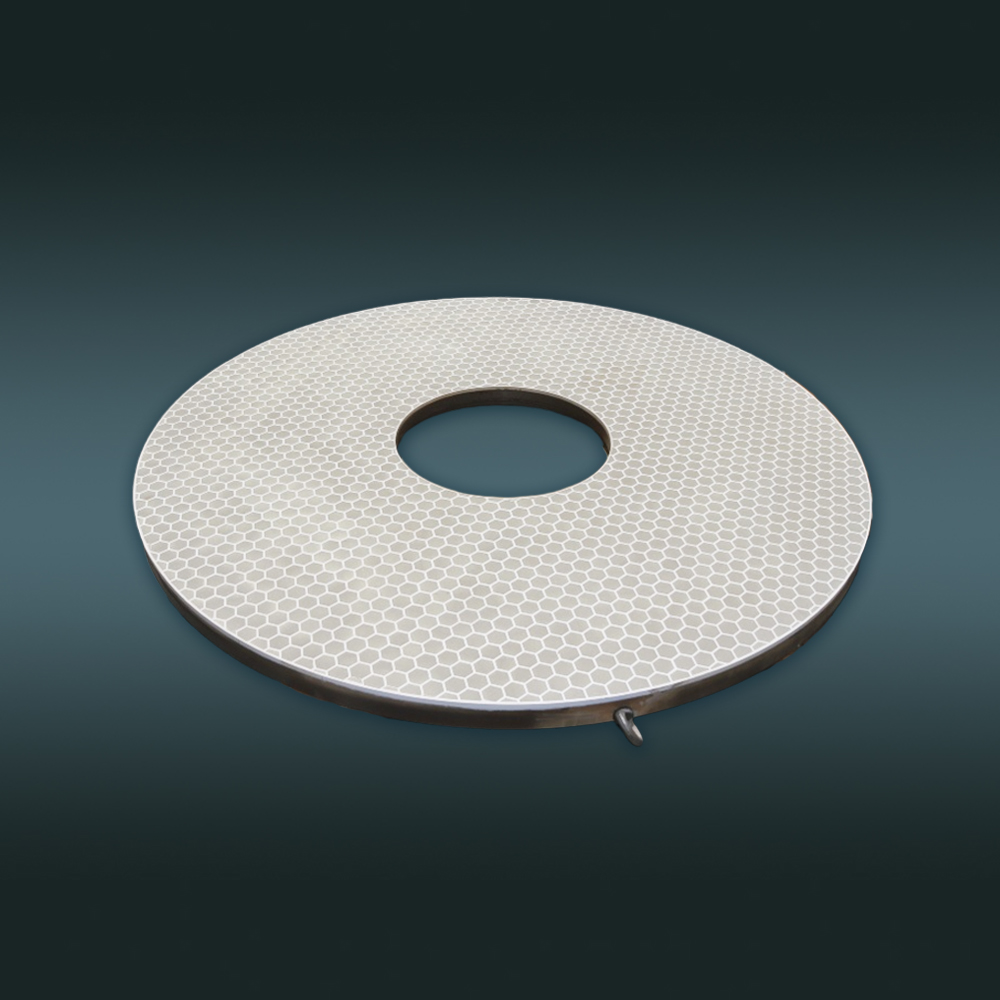

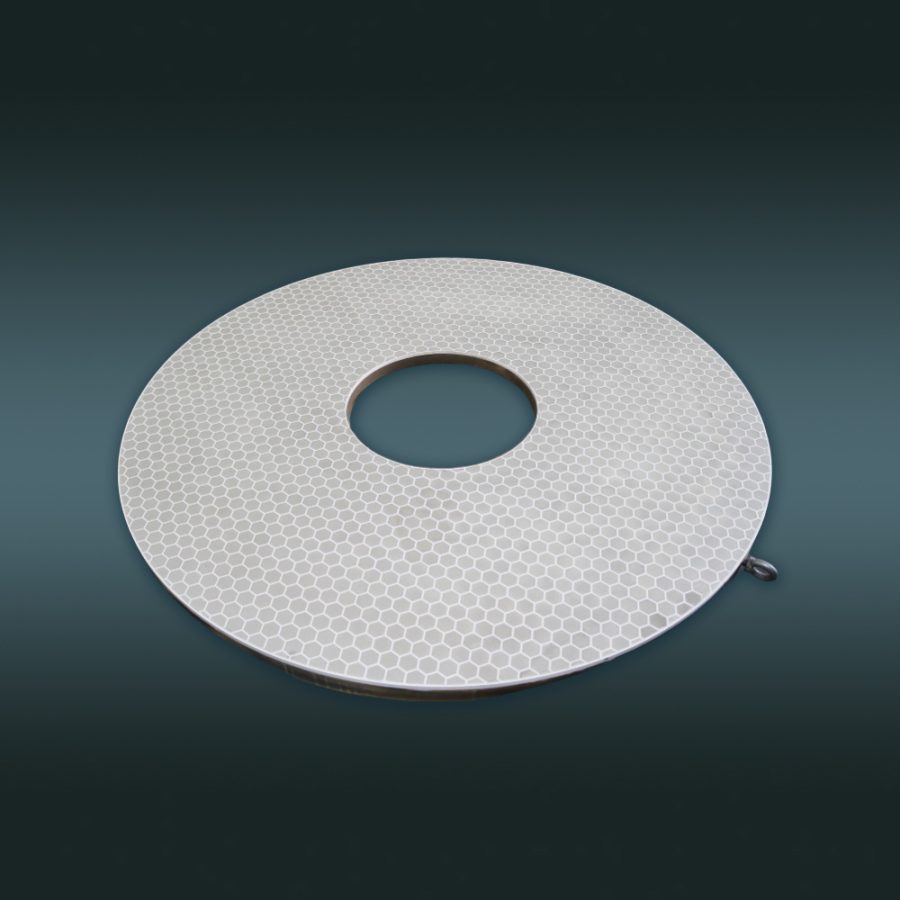

Vitrified Diamond Grinding Wheel For Grinding 2507 Stainless Steel

-

Used for grinding large stainless steel, carbide molds, optical glass components, etc.

High grinding efficiency, high processing accuracy, long service life, etc.

Minimum Order Quantity: 1pcs

Net Weight:570KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | 400/500 |

| Model Number | 1A1 |

| Outside Diameter | 1500mm |

| Total Thickness | 50mm |

| Hole | 400mm |

| Net Weight | 570KG |

| Minimum Order Quantity | 1pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for processing large stainless steel workpieces, such as stainless steel transmission shafts of ships, stainless steel cylinders of chemical reactors, etc.

- Used for processing large carbide molds: In the automotive parts manufacturing, plastic molding and other industries, it can be used for the rough grinding and fine grinding of carbide molds.

- Used for processing large optical glass components, in the fields of astronomical telescope manufacturing, large optical instrument production, etc., it can be used for the curved surface grinding and flat surface grinding of these large optical glass components.

- Used for processing large semiconductor silicon wafers, it can be used for edge grinding, back grinding and other processes of silicon wafers.

Competitive Advantage

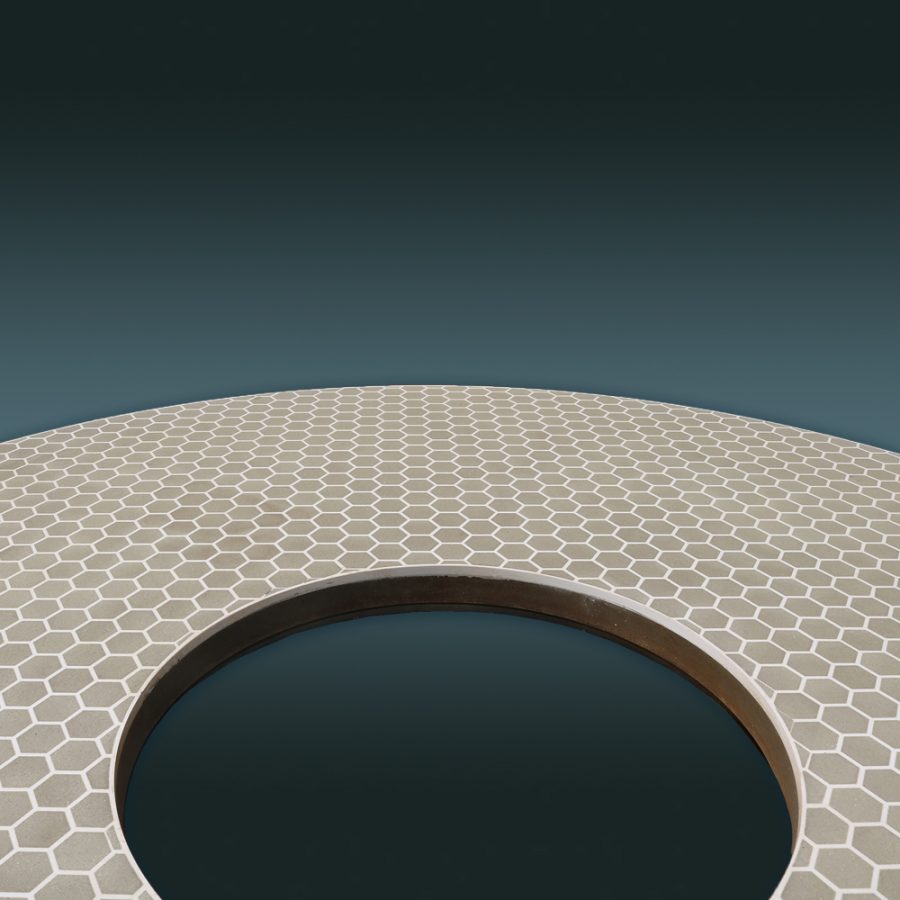

- High grinding efficiency, it can contact multiple points on the workpiece surface at the same time, and each grinding removes more material, thereby reducing grinding time and improving processing efficiency.

- High-precision processing: Due to the large diameter of the grinding wheel, it has better stability and relatively less vibration during rotation. This helps to ensure the smoothness of the grinding process, thereby achieving higher processing accuracy.

- Good surface quality, the pressure distribution per unit area is relatively more uniform, and the grinding force is relatively stable. This makes the grinding marks on the surface of the workpiece more delicate and uniform, and can obtain better surface finish and lower surface roughness, reducing the workload of subsequent polishing and other processes.

- Long service life, reducing the frequency and cost of grinding wheel replacement.

- Efficient heat dissipation helps to reduce heat accumulation in the grinding area and reduce the risk of deformation of the workpiece due to heat.