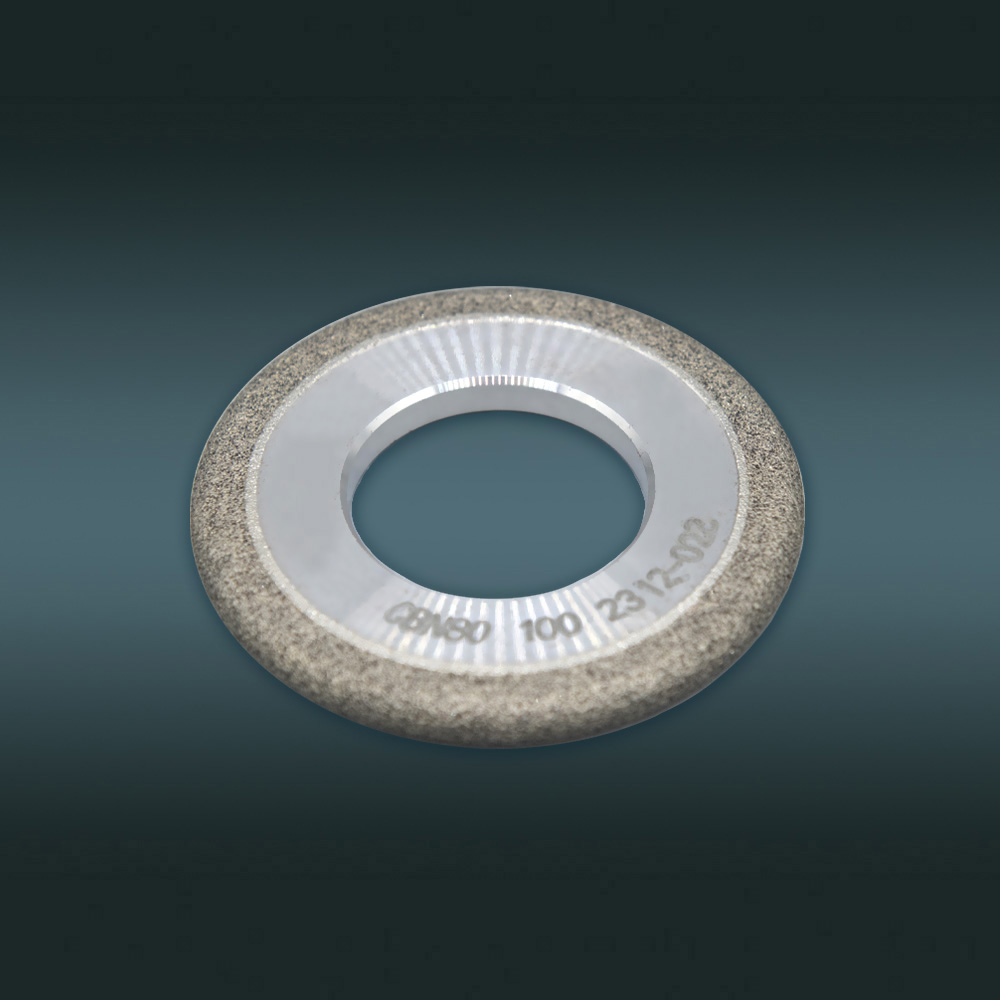

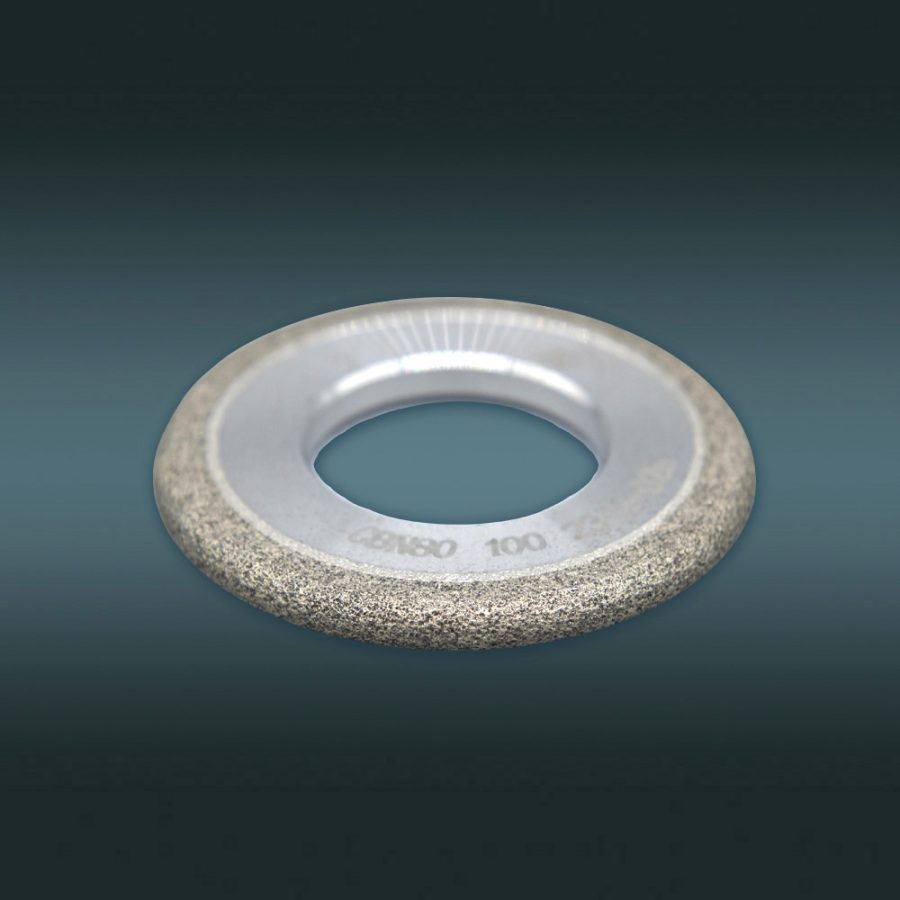

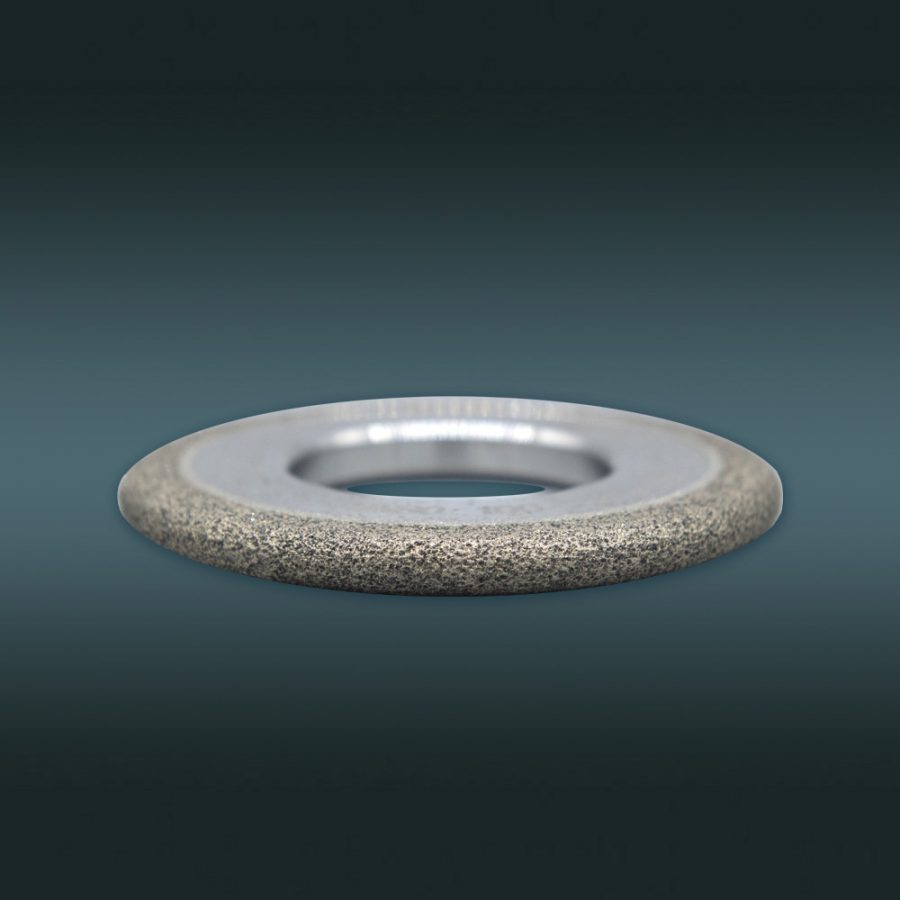

Metal Bond CBN Grinding Wheel for Grinding Hard Alloys

-

High hardness, good toughness, good thermal stability, and good processability.

Used for processing superhard materials such as black metals, hard alloys, and glass ceramics.

Minimum Order Quantity: 20pcs

Net Weight: 45g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Metal CBN grinding wheels have high hardness and toughness, good high-temperature and thermal stability, strong chemical stability, good processing performance, good economy, and environmental friendliness. They are widely used in processing superhard materials such as black metals, hard alloys, glass ceramics, and gemstones.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | CBN |

| Bond | Metal bond |

| Abrasive Grit Size | 80# |

| Model Number | 1F1 |

| Outside Diameter | 100mm |

| Net Weight | 45g |

| Minimum Order Quantity | 20pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for processing ferrous metals such as high-speed steel, tool steel, mold steel, high alloy quenched and hardened steel, etc.

- Used for processing hard alloy materials to improve processing efficiency and accuracy.

- Used for grinding hard and brittle materials such as glass and ceramics to achieve high-precision machining.

- Used for processing superhard materials such as gemstones to meet high-precision processing requirements.

Competitive Advantage

- It has good cutting force and sharper cutting effect, which can keep the particles intact and not easily broken.

- High heat resistance, no sticking phenomenon occurs when grinding and cutting iron materials, suitable for grinding metal materials.

- Not prone to chemical reactions with iron group elements, it performs well in grinding materials such as high-speed steel, mold steel, and high alloy quenched steel.

- Its high thermal conductivity helps to quickly dissipate grinding heat and reduce the thermal deformation of the workpiece.

- Long service life, low maintenance frequency, and long service life.

- The dust generated during the grinding process is relatively small, which is beneficial for environmental protection and worker health.