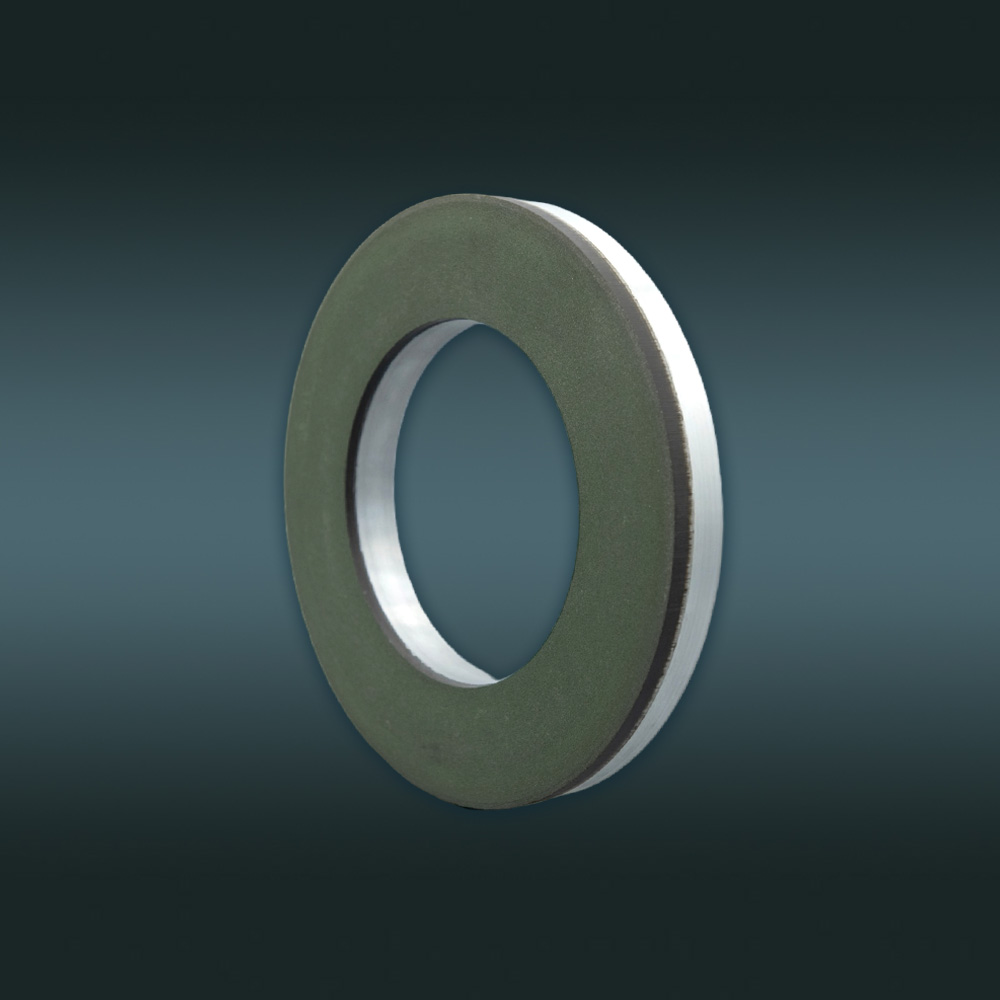

2P2 Resin diamond grinding wheel

-

Used for mold processing, mechanical parts processing, tool end face grinding, electronic component end face grinding, etc.

High grinding efficiency, high precision, good self sharpening, and good elasticity.

Minimum Order Quantity: 10pcs

Net Weight:1.6KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Diamond has extremely high hardness and can quickly remove materials during grinding of end faces, saving time. Resin binders have a certain degree of elasticity and can better adapt to the surface of the workpiece during end face grinding, reducing vibration and surface ripples, resulting in higher flatness of the end face.

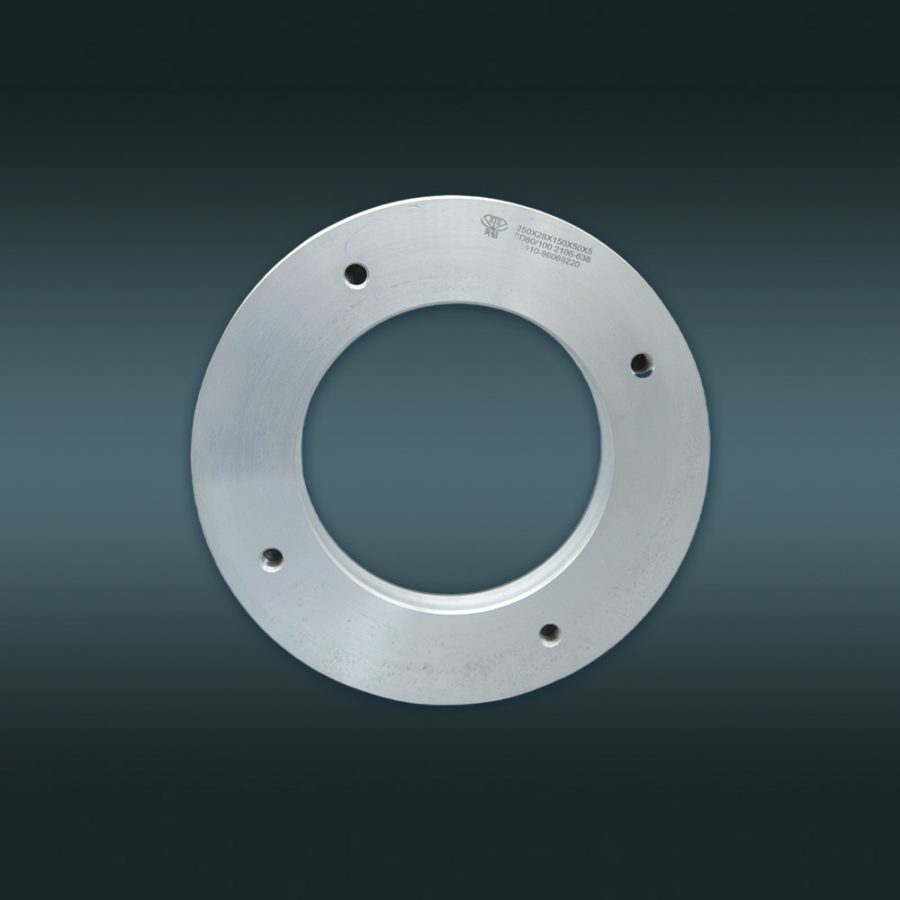

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Resin bond |

| Abrasive Grit Size | 80/100 |

| Model Number | 2P2 |

| Specification | 250*28*150*50*5 |

| Outside Diameter | 250mm |

| Hole | 150mm |

| Total Thickness | 28mm |

| Net Weight | 1.6KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for high-precision grinding of the end face of molds, such as the cavity end face of injection molds.

- Used for processing mechanical parts, such as end faces of shaft components and flange faces.

- Used for grinding the end face of cutting tools.

- High precision grinding is required for some bases used in electronic components, end faces of chip packaging, etc.

Competitive Advantage

- High grinding efficiency, capable of quickly and effectively removing materials.

- Good self sharpening, low heat generation, not easy to block, reducing the phenomenon of workpiece burns.

- Good elasticity is beneficial for improving the surface roughness of workpieces.

- Good formability, able to meet the needs of different end face grinding

- Capable of achieving high machining accuracy, ensuring the dimensional and shape accuracy of the end face.