Category

Related

-

Electroplated diamond grinding wheel for tire mold manufacturing

-

Electroplated Diamond Hand Polishing Pads for Glass Granite Marble Concrete Sanding Blocks

-

Superhard Material Products Saw Blade Electroplated Diamond Dresser Wheel for Auto Parts

-

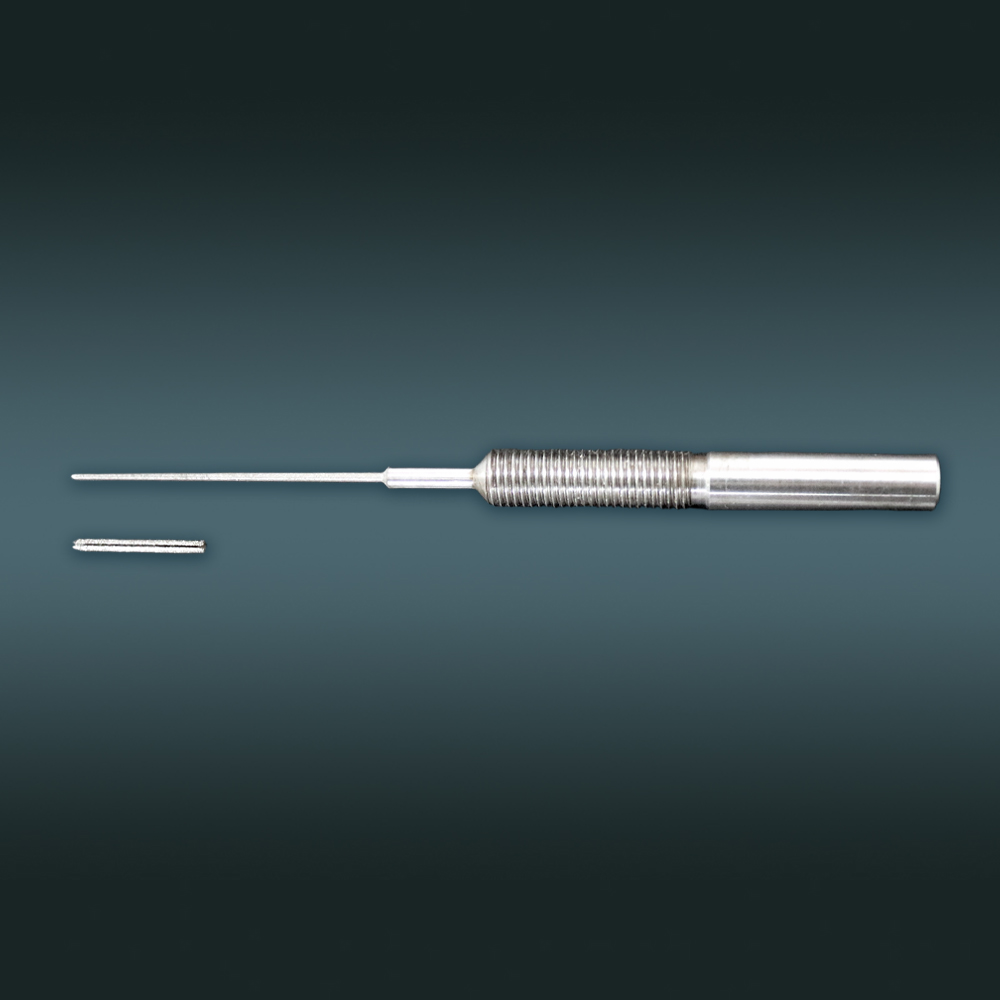

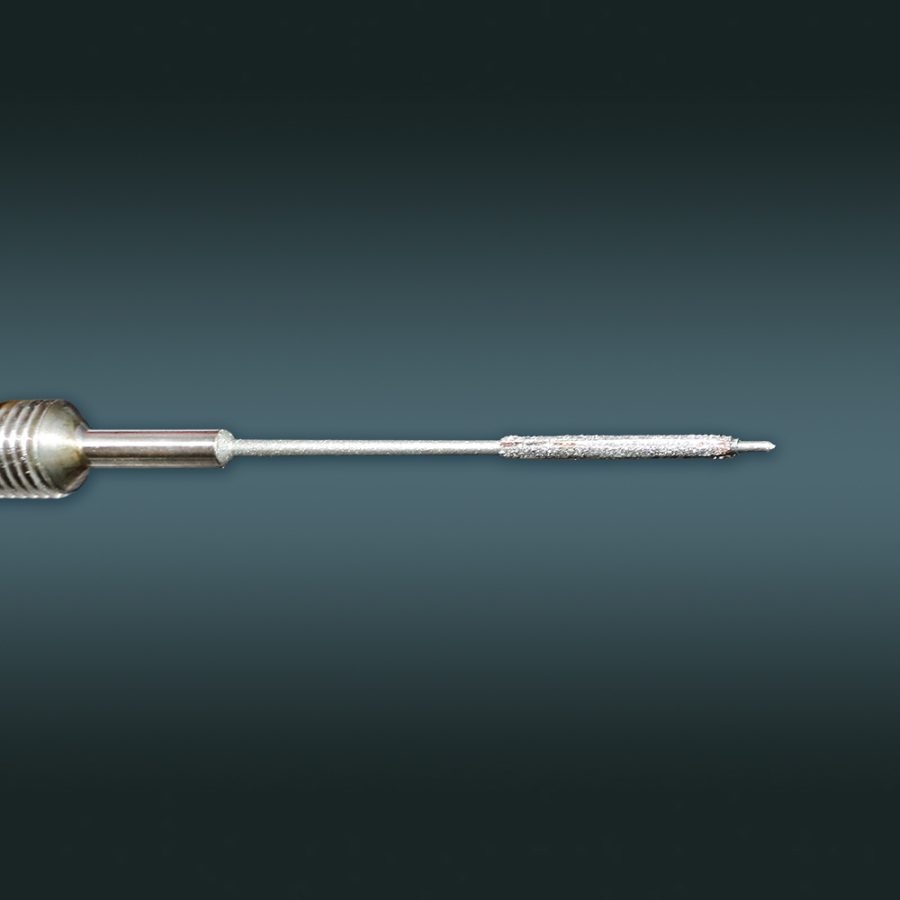

Electroplated diamond & CBN grinding rod for inner edge grinding

-

Electroplated diamond grinding wheel for glass edge grinding

Detail

Description

The electroplated diamond honing grinding head is a tool used for precision machining, primarily for honing, grinding, and polishing inner holes, outer circles, or complex curved surfaces. Its abrasive particles are evenly distributed and have high bonding strength, which is suitable for high-precision and high-surface quality processing scenarios.

Applications

Used for honing of automobile engine cylinder sleeves/hydraulic valve holes. After diesel engine cylinder sleeves are processed, oil consumption can be reduced by 15%~20%.

Used for processing of high-temperature alloy parts such as tenons and nozzles of aerospace turbine blades. After honing of engine nozzles, airflow uniformity can be improved by 12%.

Used for precision polishing of carbide/ceramic molds. After polishing of mobile phone glass molds, product yield can be increased from 85% to 98%.

Used for honing of medical devices such as artificial joints and surgical instruments. After processing of titanium alloy artificial hip joint ball heads, the wear rate can be reduced by 30%.

Used in the electronics industry such as semiconductor ceramic rings and optical lens barrels. After honing of fiber optic connector ceramic sleeves, the insertion loss can be reduced to below 0.2dB.

Competitive Advantage

High precision: Surface roughness below Ra 0.1μm and dimensional accuracy ±0.005mm can be achieved.

Long life: Diamond has excellent wear resistance and is suitable for high-hardness materials (such as hardened steel and tungsten carbide).

Wide adaptability: Customizable shape and particle size for complex geometric shapes.

Low cooling requirements: Electroplated grinding heads have better heat dissipation than resin/metal bonded abrasives.

Dry/wet dual use: Suitable for oilstone honing or dry processing scenarios.

FAQ:

Q: Can electroplated honing heads repair worn holes?

A: They can be repaired, but a margin must be reserved (recommended 0.02-0.05mm), and coarse-grained honing heads (such as 120#) are preferred.

Q: What is the recommended particle size?

A: Roughing: 80#-150#, which can quickly remove the margin. Finishing: 180#-400#, which can obtain high surface quality.

Q: What is the difference with sintered honing heads?

A: Electroplated heads are sharper and less expensive, suitable for small batches; sintered heads have a longer life and are suitable for mass production.

Q: How to maintain?

A: Regularly trim with oilstone strips (every 50-100 holes are processed), and moisture-proof during storage to avoid acid-base environment corrosion of the electroplating layer.

Q: Are there any process requirements?

A: The recommended line speed is 30-60m/min, and the feed rate is 0.05-0.2mm/stroke. The coolant is preferably low-viscosity honing oil (such as kerosene-based) to avoid clogging by abrasive particles.