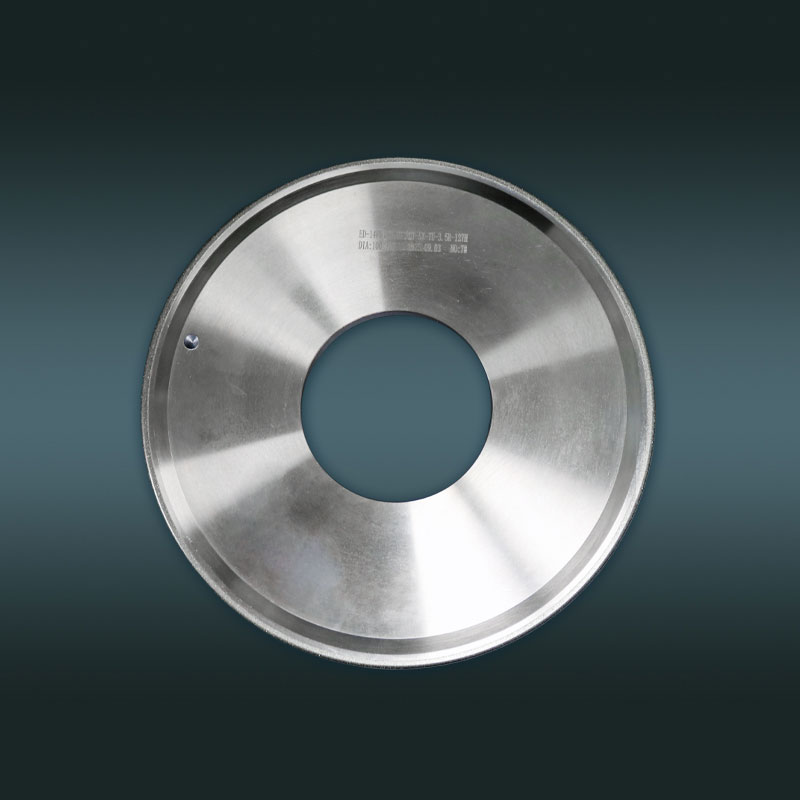

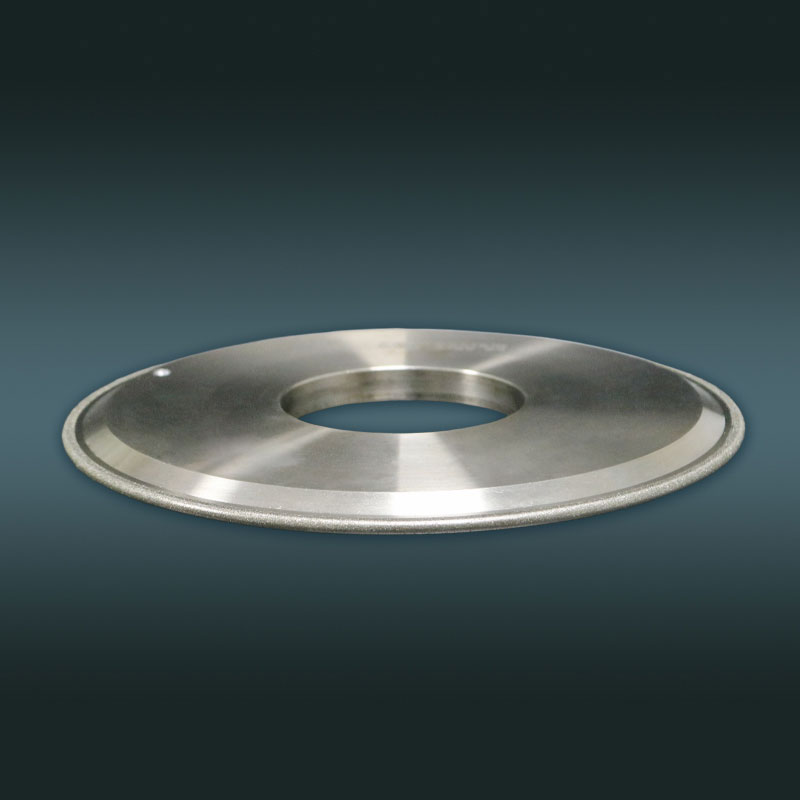

Electroplated Diamond Grinding Wheels for Steel Mill Rolls

-

Customized for international customers, specifically for processing steel mill rolls.

High hardness, high efficiency, good formability, and no need for trimming.

Minimum Order Quantity: 10pcs

Net Weight: 15KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

This electroplated diamond grinding wheel is a highly efficient, high-precision tool for repairing and texturing rolls in steel mills, particularly high-hardness rolls. Its exceptional hardness, sharpness, and excellent formability make it an irreplaceable tool for ensuring roll repair quality, improving efficiency, and extending roll life.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

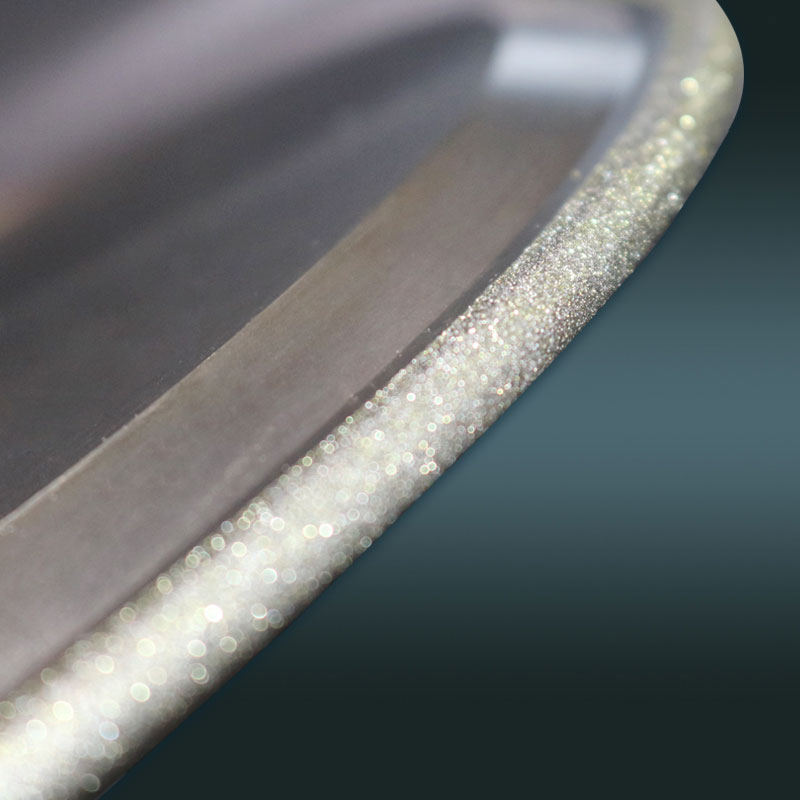

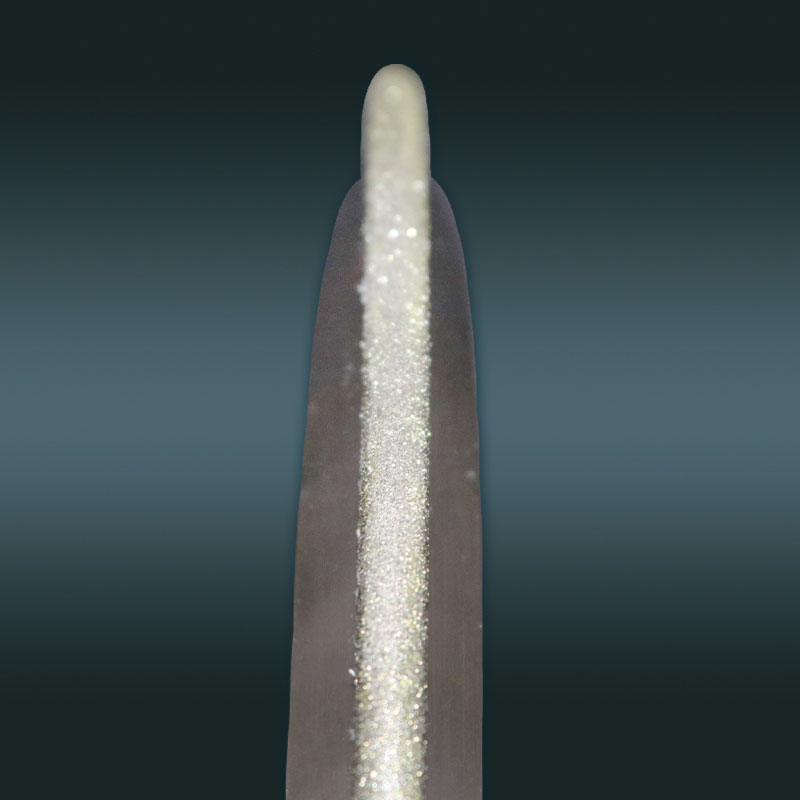

| Abrasive | Diamond |

| Bond | Electroplated bond |

| Abrasive Grit Size | 100/120 |

| Model Number | 14A1 |

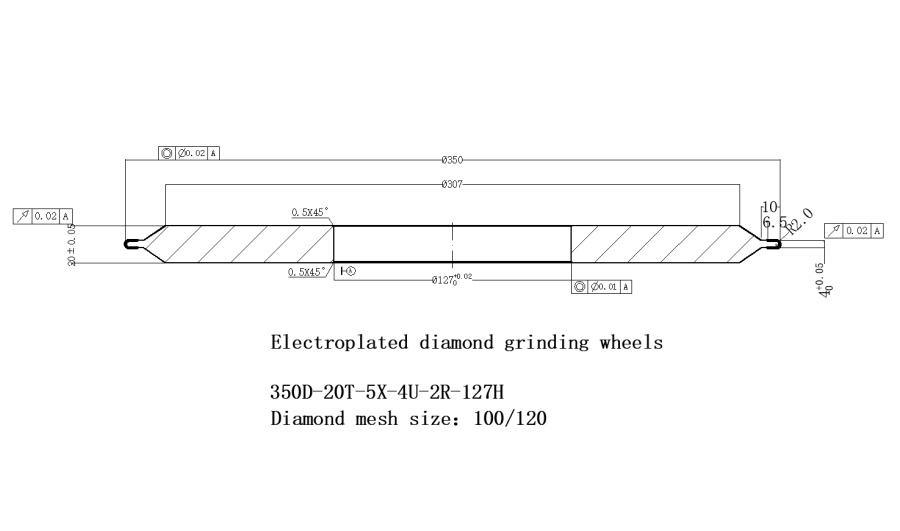

| Specification | 350D-20T-5X-4U-2R-127H |

| Net Weight | 15KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Drawings

Applications

1. Used for rough grinding and cylindrical grinding of rolls in steel mills, it can quickly remove wear layers and fatigue cracks on the roll surface, restoring its basic dimensions and roundness.

2. Used for fine grinding and superfinishing of rolls in steel mills, it can achieve extremely high dimensional accuracy and extremely low surface roughness (Ra values can reach below 0.1μm).

3. Used for texturing of rolls in steel mills, one of the most critical applications. Electroplated diamond grinding wheels regularly grind or "carve" the roll surface, creating a uniform, controllable microtopography (rough surface). This rough surface retains rolling oil during cold rolling and imparts specific surface qualities to the steel sheet, such as the excellent paintability required for automotive sheet metal. This process is also known as EDT technology.

4. Used for groove and profile grinding of rolls in steel mills, it can produce a variety of grooves and special profiles on rolls.

Competitive Advantage

- It offers exceptional hardness and wear resistance, maintaining long-lasting sharpness on roll materials such as high-chromium iron.

- Low grinding forces and heat generation: Due to its sharpness and high efficiency, grinding forces and heat generation are low per unit time, effectively preventing burns on the roll surface and preserving its metallurgical properties.

- Excellent formability allows for easy fabrication into various complex shapes (such as arcs and V-grooves) for grinding specific roll profiles.

- Electroplated grinding wheels generally require no dressing during their lifespan, making them easy to use.

- High grinding efficiency: Under appropriate process parameters, efficient grinding can be achieved, improving roll repair efficiency.