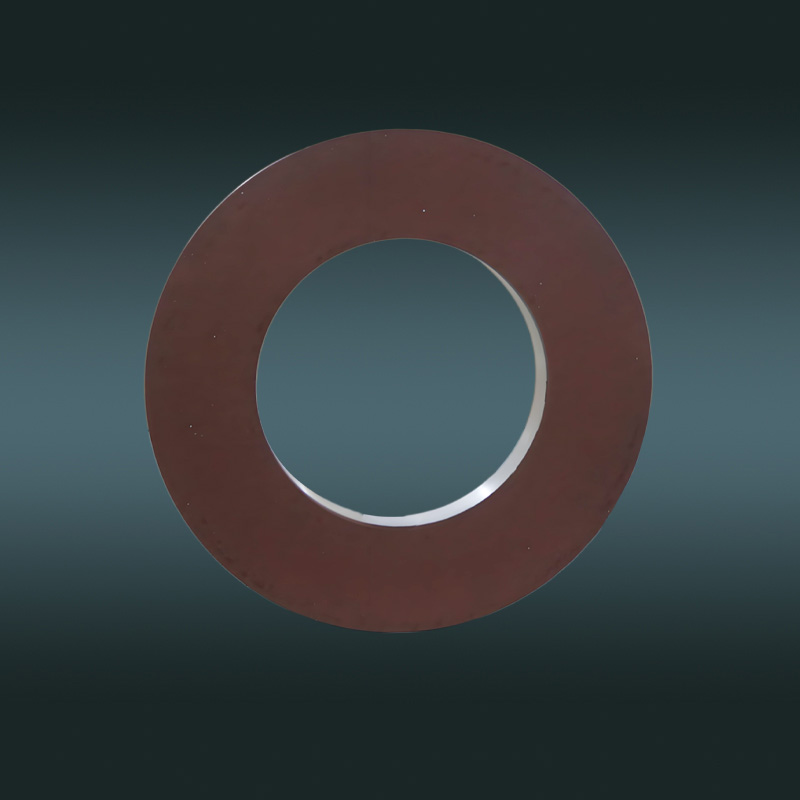

Resin Diamond Grinding Wheel for NdFeB magnets

-

Used for forming and grinding various neodymium iron boron magnets.

High efficiency, not prone to clogging, good heat dissipation, strong stability, and long service life.

Minimum Order Quantity: 10pcs

Net Weight: 11KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

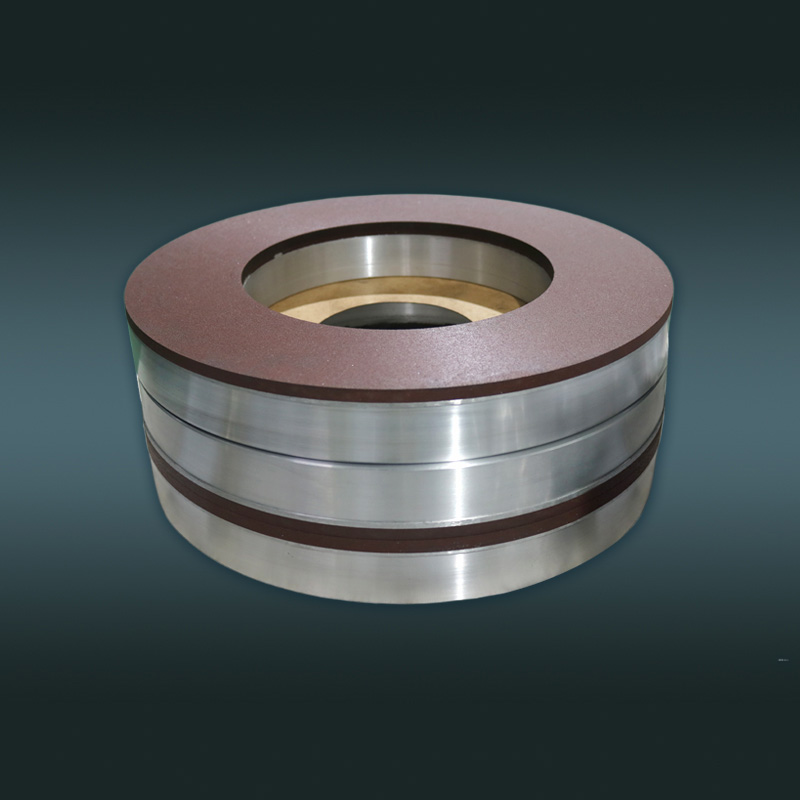

This resin bond diamond grinding wheel can be used on large vertical shaft surface grinders. It is a heavy-duty grinding tool for large-scale, high-efficiency, and long-life roughing of NdFeB blocks, and is used for the first shaping grinding of sintered NdFeB blank blocks.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

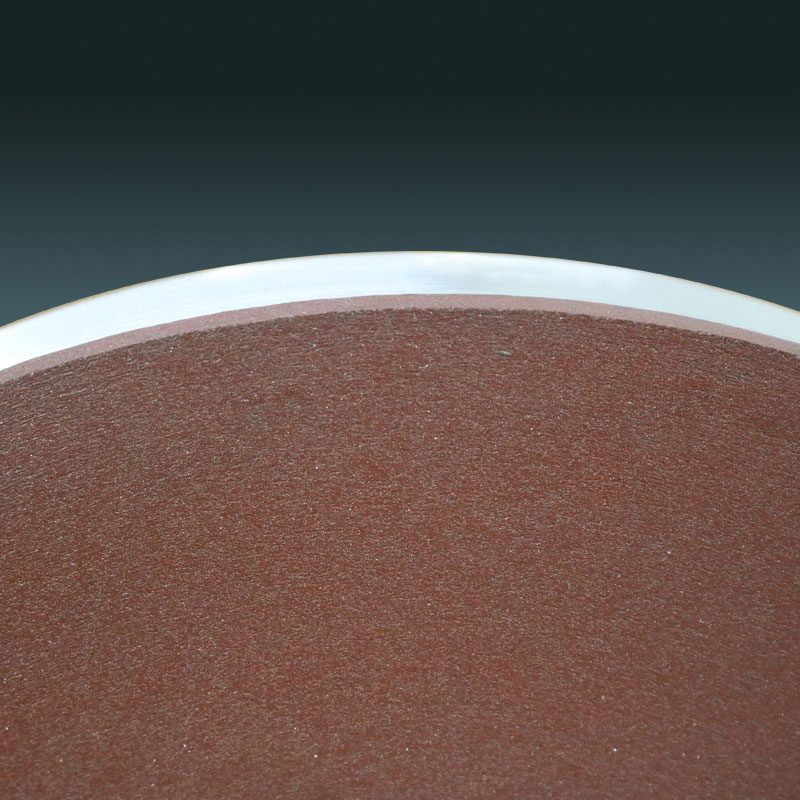

| Abrasive | Diamond |

| Bond | Resin |

| Abrasive Grit Size | 60# |

| Model Number | 2A2T |

| Specification | 400*50*230*85*5.5 |

| Net Weight | 11KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

1. Used for arc surface grinding of magnetic tiles, typically on a double-end face grinder or a dedicated arc surface grinder.

2. Used for grinding square or rectangular NdFeB magnets of various sizes. Utilizing the 85mm wide toroidal surface of the grinding wheel, the upper and lower large planes of the magnet can be ground efficiently. Multiple sides of the magnet can also be ground by adjusting the machine tool to ensure perpendicularity and dimensional accuracy.

3. Used for grinding one or two end faces of toroidal magnets to ensure thickness and parallelism.

4. Used for shaping irregularly shaped magnets. Shape grinding can be performed by dressing the grinding wheel profile or using specific CNC paths.

Competitive Advantage

- High efficiency, enabling highly effective material removal.

- It is not prone to clogging and has excellent heat dissipation, quickly removing the large amount of heat and NdFeB debris generated during grinding, reducing workpiece "burning" (burning severely affects the magnetic properties of NdFeB).

- It has high rigidity and stability, able to withstand the enormous grinding forces generated during rough machining, ensuring smooth processing and maintaining good flatness.

- It has a long service life and good self-sharpening properties, reducing the frequency of replacement and maintenance, thereby improving equipment utilization and reducing costs.

- The resin has good elasticity, acting as a buffer to reduce material chipping and micro-cracks.