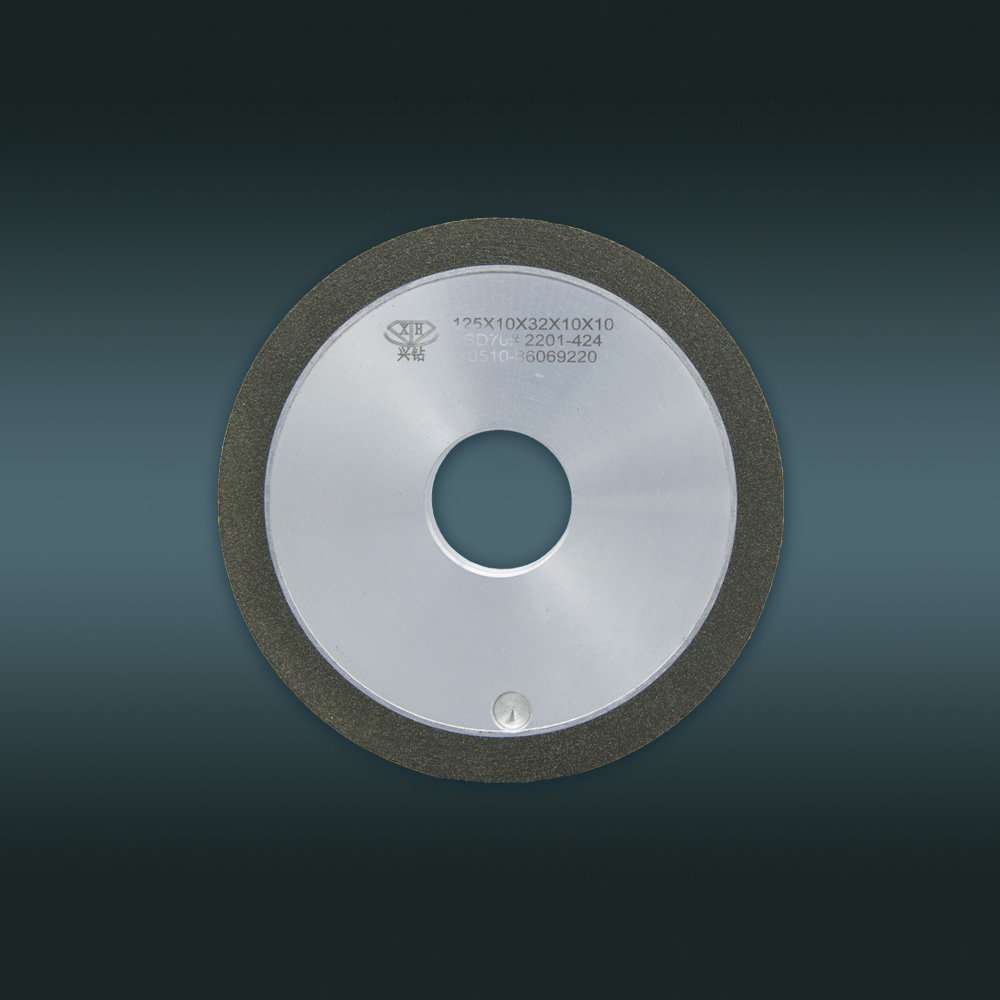

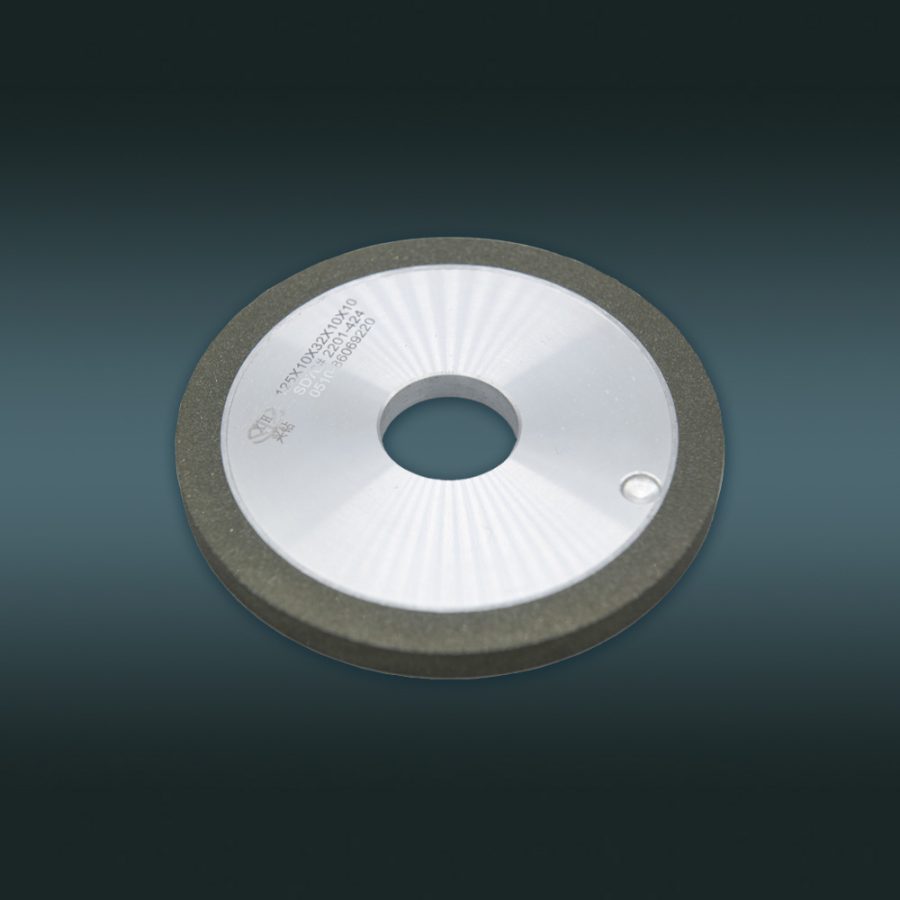

Parallel resin diamond grinding wheel

-

Suitable for processing hard alloys, cutting tools, tungsten steel, stainless steel, ceramics, glass, and semiconductor materials.

High grinding efficiency, good self sharpening, low heat generation, and high stability.

Minimum Order Quantity: 10pcs

Net Weight: 350g

Payment:30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Parallel resin diamond grinding wheel is an important grinding tool. Its grinding accuracy is high, and its parallel structure ensures that it can better control the flatness of the grinding process. At the same time, the elasticity of the resin binder helps to buffer the impact force generated during grinding, reduce surface damage to the parts, and lower the wear and tear of the grinding wheel itself.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Resin bond |

| Model Number | 1A1 |

| Abrasive Grit Size | 70# |

| Specification | 125*10*32*10*10 |

| Outside Diameter | 125mm |

| Hole | 32mm |

| Net Weight | 350g |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding, slotting, and sharpening of hard alloy cutting tools, molds, drill bits, etc.

- Perform operations such as external cylindrical grinding and surface grinding on tungsten steel materials.

- Used for grinding, polishing, etc. of stainless steel materials.

- Used for cutting, grinding, and polishing ceramic tiles, ceramic tubes, ceramic crafts, etc.

- Cut, grind edges, drill holes, etc. on glass.

- Used for slicing, grinding, polishing, etc. of semiconductor silicon wafers, gallium arsenide and other materials.

- Perform external cylindrical grinding on various shaft components.

- Used for gear profile grinding, tooth surface polishing, etc.

- High grinding efficiency, which can maintain the sharpness and grinding efficiency of the abrasive.

- Good self sharpening ability and long retention time of cutting ability.

- Elastic, able to better fit the surface of the workpiece and reduce grinding vibration.

- Low heat generation reduces the risk of burns and deformation of the workpiece due to overheating.

Competitive Advantage