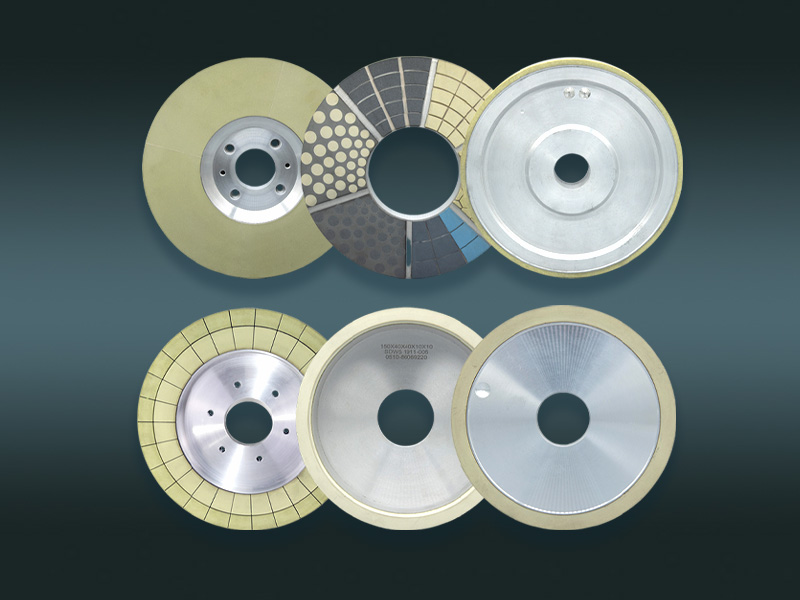

Diamond Wheel For PCD Tools

-

Diamond grinding wheels have high grinding efficiency, long life, are not prone to heat and clogging, and are easy to control machining accuracy and dressing. They are suitable for PCD and PCBN tool material processing. We can provide vitrified bond diamond grinding wheels and design and manufacture various non-standard grinding tools according to your requirements. They are suitable for precision grinding of super-hard tools, end faces, bevels, holes, etc.

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Do we need a diamond grinding wheel or a CBN grinding wheel to grind PCD?

Because PCD has extremely high hardness, ordinary grinding wheels cannot be used. Diamond grinding wheels are usually chosen to process PCD tools.

What kind of bond diamond grinding wheel can you choose?

vitrified bond

Vitrified bond diamond grinding wheels are the first choice for grinding PCD. It has the characteristics of high strength, good heat resistance, sharp cutting, and high grinding efficiency. It is not easy to heat and block during the grinding process. It has a small thermal expansion and can control the processing accuracy. It can effectively ensure the edge quality and processing accuracy of PCD tools. , suitable for rough grinding, fine grinding, and polishing of PCD.

resin bond

Resin bond diamond grinding wheels have good self-sharpening properties and generate less heat during grinding. They are suitable for fine grinding and form grinding of PCD. However, its bonding strength is relatively low. When grinding harder PCD materials, the grinding wheel wears faster and the grinding efficiency is lower than that of vitrified bond diamond grinding wheels. However, for some grinding wheels with higher surface quality requirements and grinding allowance For smaller PCD workpieces, resin bond diamond grinding wheels still have certain application value.

Why choose our products?

1. We use better diamond abrasives and imported binders to ensure good raw materials and good product quality.

2. We have professional engineers to supervise and control production and a strict quality inspection department to ensure product quality again.

3. We can customize according to customer needs and use special formulas to ensure good grinding effects, high grinding efficiency, and long service life.

4. We have a good sales team, after-sales team, and technical team to provide customers with free services at any time to ensure that there are no problems with customers' use.