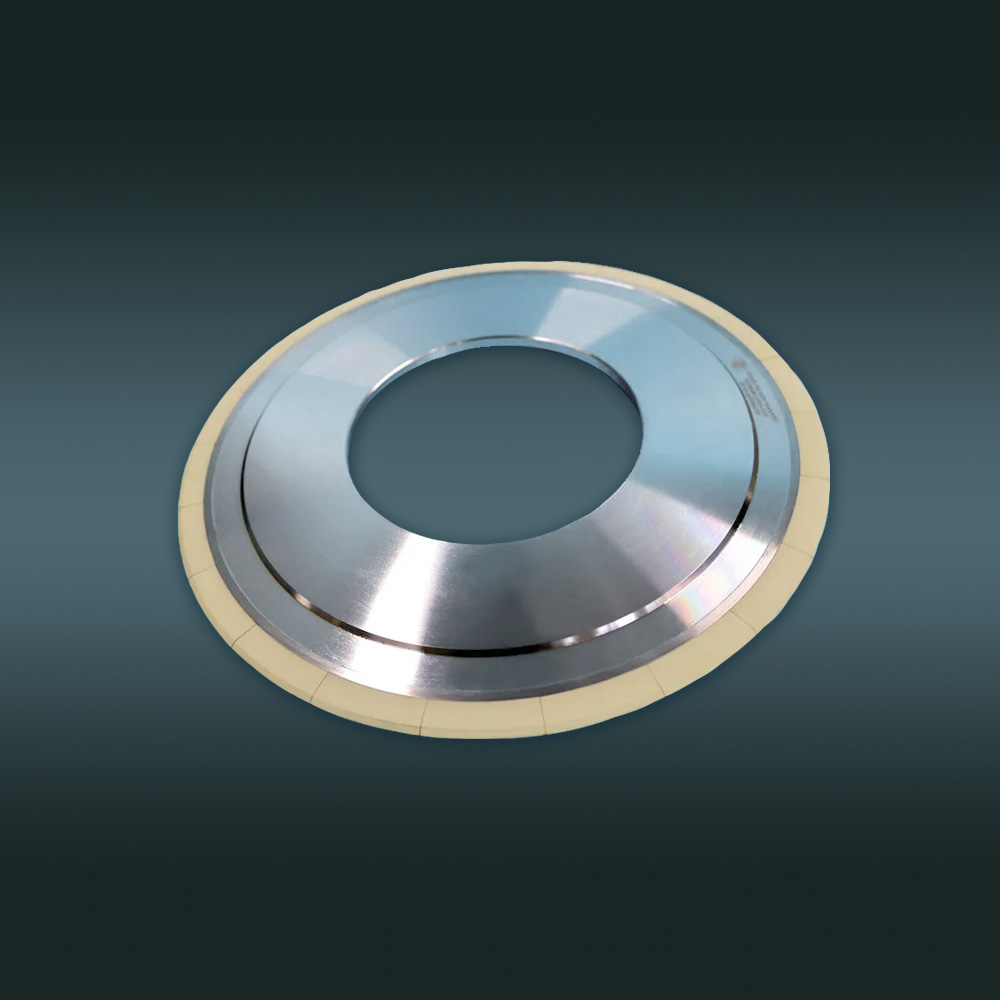

Vitrified Diamond Grinding Wheel For Tungsten Steel Knife Tap

-

Vitrified diamond Grinding wheels are ideal for grinding tungsten steel, knives and taps.

High hardness, good wear resistance, high strength, good heat resistance, sharp.

Minimum Order Quantity: 10pcs

Net Weight: 1.7KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Vitrified diamond grinding wheels have high hardness and can effectively grind tungsten steel, a material with high hardness and strong wear resistance while maintaining good cutting performance and reducing grinding wheel wear and replacement frequency.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | 170/200 |

| Model Number | 14A1 |

| Outside Diameter | 350mm |

| Net Weight | 1.7KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

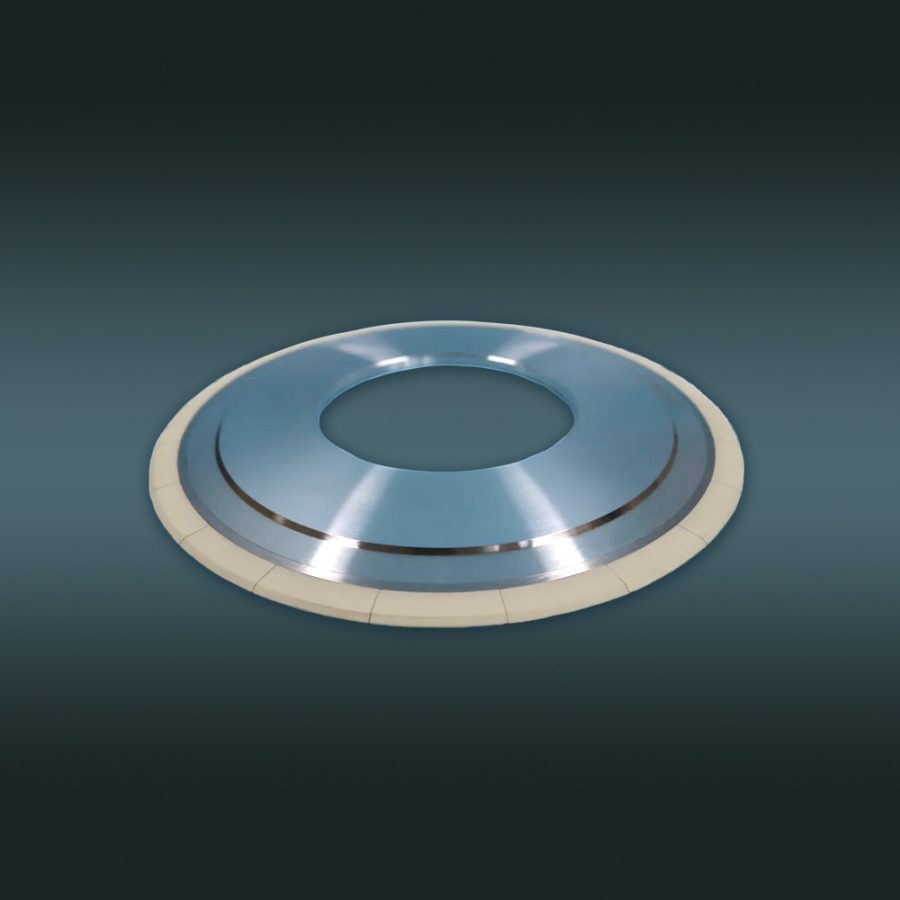

Applications

Used for grinding tungsten steel, a material with high hardness and strong wear resistance.

It can quickly remove tungsten steel materials and improve grinding efficiency.

It can reduce the risk of deformation, cracks and other defects caused by overheating of tungsten steel tools and taps.

It is used for grinding tungsten steel knives and taps with high precision requirements.

Competitive Advantage

High hardness and good wear resistance can keep the grinding wheel in good cutting performance.

High strength and good heat resistance, the grinding wheel can withstand the high temperature generated during grinding.

Sharp cutting and high grinding efficiency can quickly remove tungsten steel materials.

Less heat is generated, which can reduce the risk of deformation, cracks and other defects caused by overheating of tungsten steel tools and taps.