Why Vitrified Bond Grinding Wheels Are Perfect for High-Precision Grinding

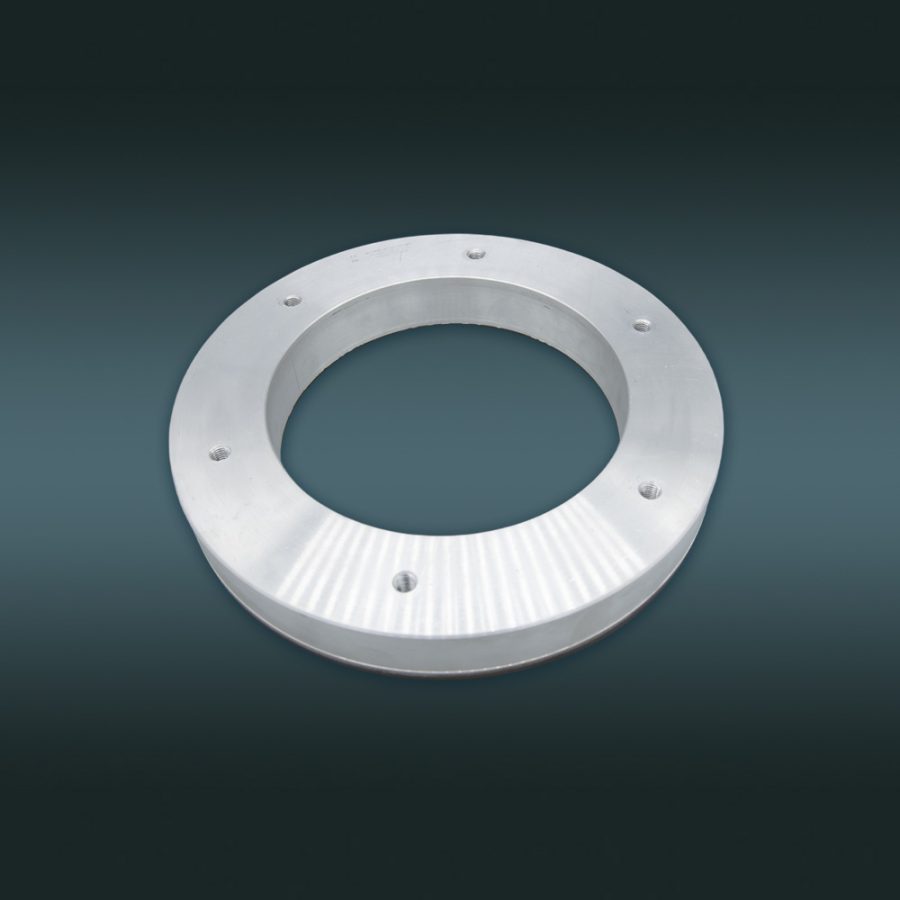

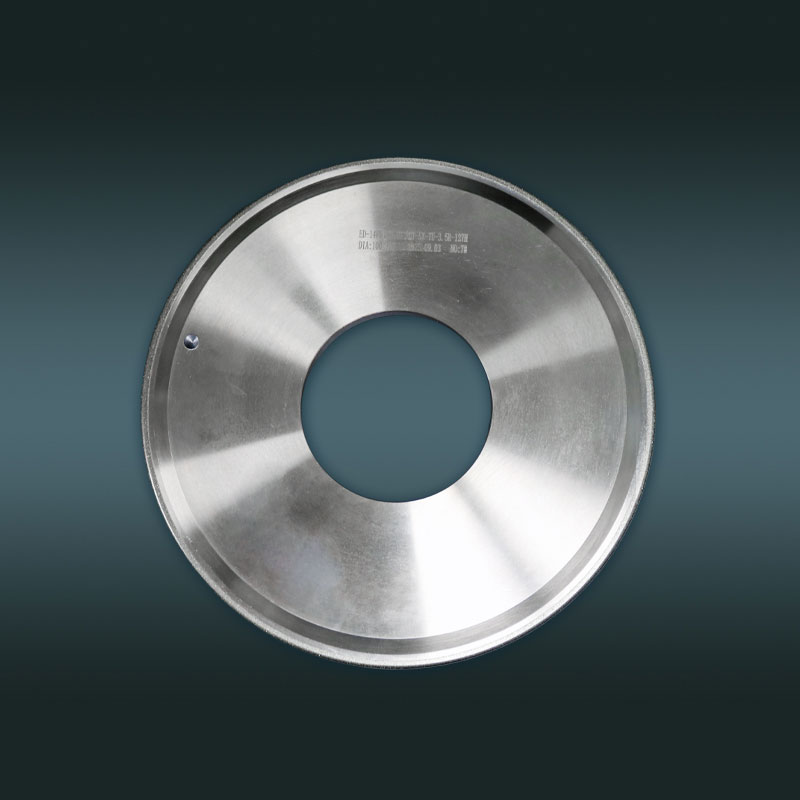

Vitrified bond grinding wheels are widely recognized as one of the most reliable solutions for high-precision grinding applications. Their unique bonding structure, combined with excellent mechanical stability and thermal performance, makes them a preferred choice in industries where accuracy, consistency, and surface quality are critical. As manufacturing standards continue to rise, vitrified bond wheels play an increasingly important role in precision machining. The defining feature of vitrified bond grinding wheels is their ceramic-based bonding material. This bond is formed by fusing abrasive grains with glass-like materials at high temperatures, creating a rigid and porous structure. The result is a grinding wheel with excellent hardness and dimensional stability, which is essential for maintaining tight tolerances during precision grinding operations.

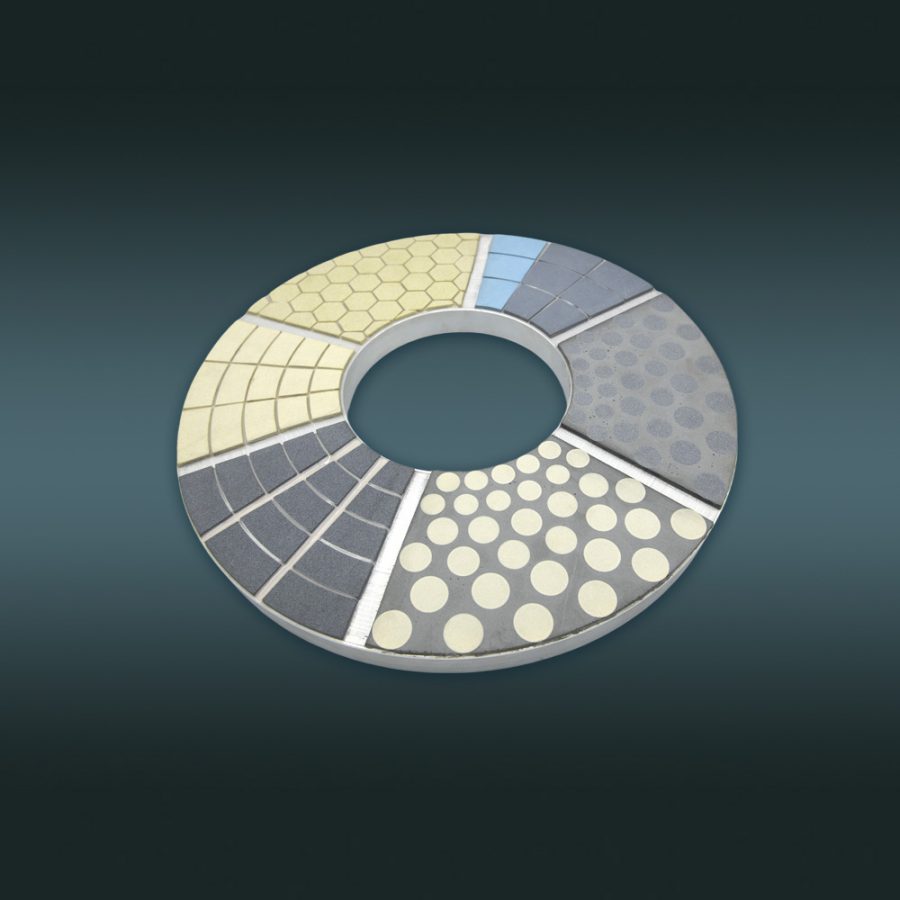

One of the most significant advantages of vitrified bond grinding wheels is their superior shape retention. Unlike softer bonds that may deform under pressure, vitrified bonds maintain their original geometry even during long grinding cycles. This ensures consistent grinding accuracy and repeatable results, which is especially important in applications such as mold manufacturing, precision tooling, optical components, and aerospace parts. Controlled porosity is another key benefit of vitrified bond wheels. The porous structure allows effective chip removal during grinding, preventing clogging and maintaining sharp cutting edges. At the same time, these pores facilitate efficient coolant flow to the grinding zone, helping to reduce heat generation and protect both the workpiece and the grinding wheel from thermal damage.

Thermal stability is a critical factor in high-precision grinding, and vitrified bond grinding wheels excel in this area. Their resistance to high temperatures minimizes the risk of wheel deformation, surface burns, and micro-cracks on the workpiece. This makes them particularly suitable for grinding hardened steels, alloys, and other materials that are sensitive to heat and require precise dimensional control. Vitrified bond grinding wheels also offer excellent dressing performance. They can be easily dressed to restore cutting sharpness, adjust wheel profile, and maintain grinding accuracy throughout their service life. This ability to be dressed precisely allows manufacturers to fine-tune the grinding process, achieving optimal surface finishes and consistent part quality over extended production runs.

In terms of surface finish, vitrified bond wheels deliver outstanding results. The stable bond and uniform abrasive distribution allow for controlled material removal, producing smooth and high-quality surfaces. This is crucial for components that require minimal post-processing, such as precision bearings, medical instruments, and high-end mechanical parts. Another important advantage is process reliability. Vitrified bond grinding wheels provide predictable and stable grinding behavior, which simplifies process control and reduces production variability. This reliability helps manufacturers improve yield rates, minimize scrap, and maintain strict quality standards in mass production as well as high-value custom machining.

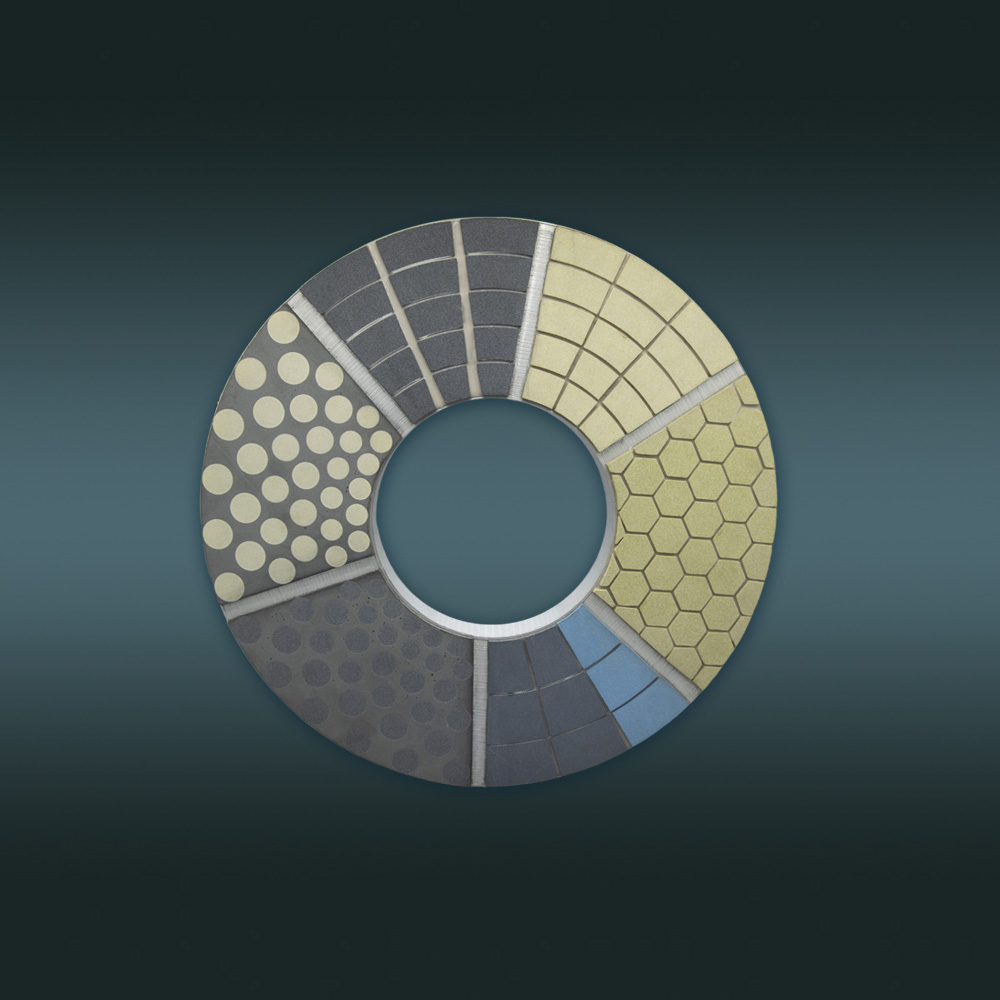

Vitrified bond wheels are also versatile and can be engineered for a wide range of applications by adjusting abrasive type, grain size, bond composition, and porosity. This flexibility allows manufacturers to develop customized solutions tailored to specific materials, machines, and precision requirements, further enhancing their suitability for advanced grinding tasks. In conclusion, vitrified bond grinding wheels are perfectly suited for high-precision grinding due to their exceptional shape retention, thermal stability, controlled porosity, and consistent performance. Their ability to deliver accurate, repeatable results with excellent surface quality makes them an indispensable tool in modern precision manufacturing. For industries where precision is non-negotiable, vitrified bond grinding wheels remain a trusted and proven solution.