Vitrified CBN Grinding Wheel Sales Training Conference

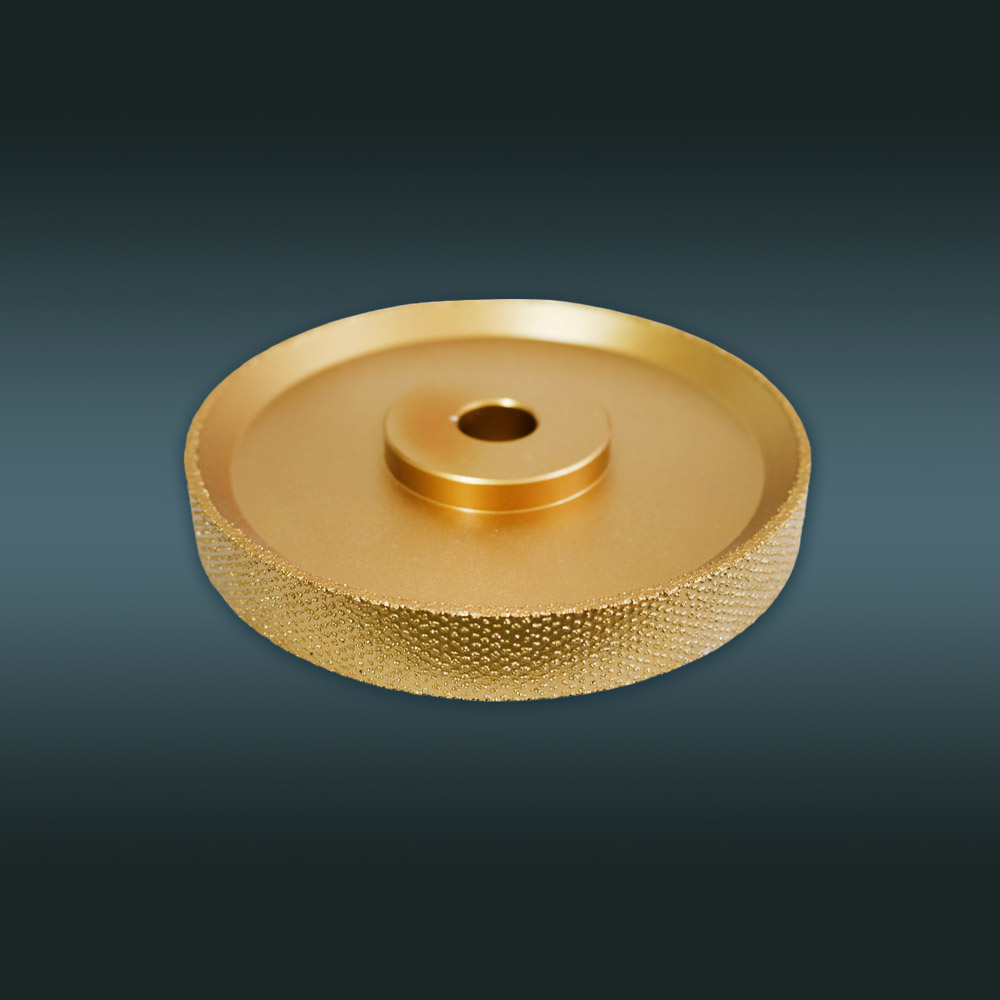

Our company organized a special sales training meeting on May 6, focusing on sharing the successful cases of vitrified CBN grinding wheels in camshaft grinding. With the continuous improvement of the requirements for parts processing accuracy and efficiency in the automotive, aviation, precision machinery and other industries, the grinding process of camshafts and screw bottom diameters faces higher challenges. We have successfully applied vitrified CBN grinding wheels to this field, achieving high-precision, long-life, low-cost grinding solutions, helping customers reduce costs and increase efficiency.

Camshaft grinding - high precision, high stability

Industry pain points: The complex camshaft profile and traditional grinding wheels are prone to wear, resulting in dimensional fluctuations and substandard surface roughness.

Our solution: Use high-toughness vitrified CBN grinding wheels and precision dressing technology to ensure profile accuracy. The high thermal stability of CBN abrasive grains effectively reduces grinding burns, and the surface roughness can reach Ra≤0.2μm. After using it, the customer's grinding wheel life is increased by 3 times, and the processing cost per piece is reduced by 30%.

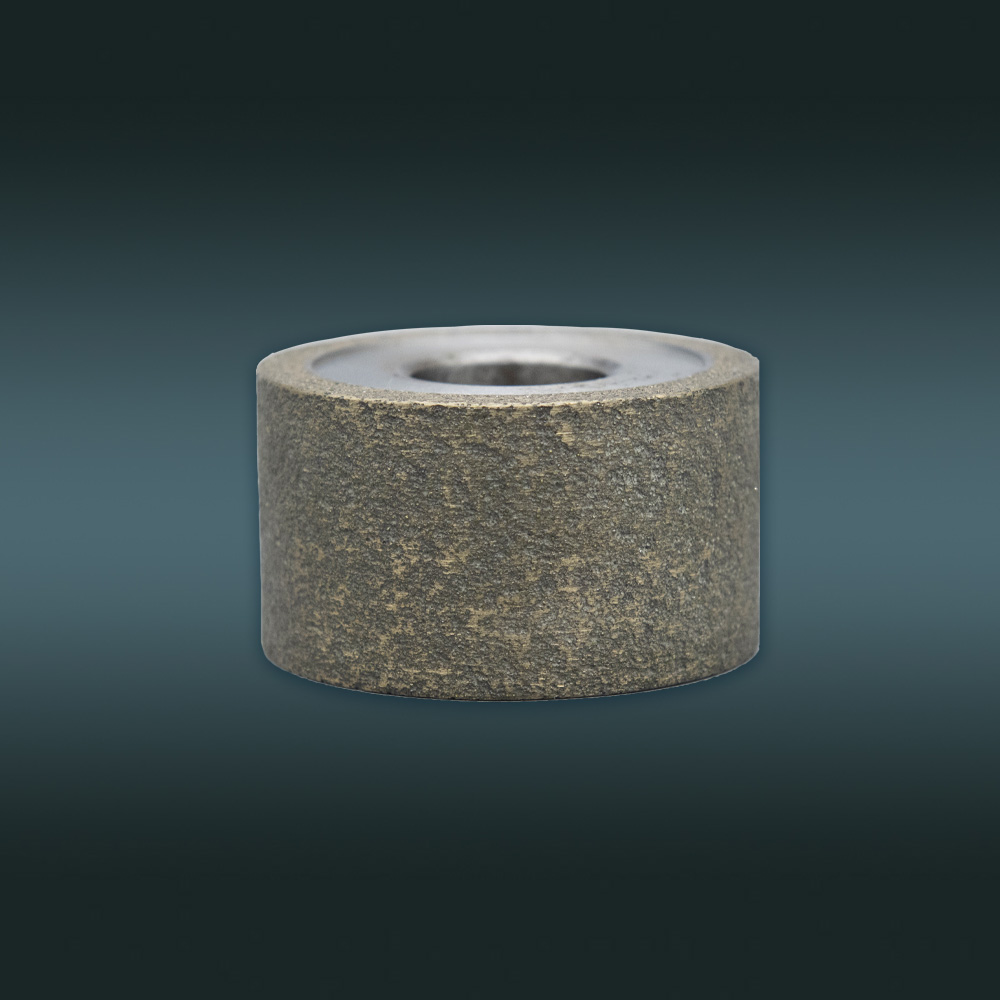

Screw bottom diameter grinding - efficient processing, long life

Industry demand: The bottom diameter grinding of screw parts (such as compressor screws) requires extremely high wear resistance and shape retention of the grinding wheel.

Our solution: Customized porous vitrified CBN grinding wheel, optimized porosity, improved chip removal capacity, and avoided clogging. Combined with a special binder formula, the grinding wheel life is extended by more than 50% compared with traditional products, greatly reducing the downtime for wheel change. Customer feedback shows that the processing efficiency has increased by 25%, and the yield rate exceeds 99%.

Our advantages:

Mature technology: more than 20 years of experience in CBN grinding wheel research and development, process parameter database covers a variety of materials (cast iron, alloy steel, hardened steel, etc.).

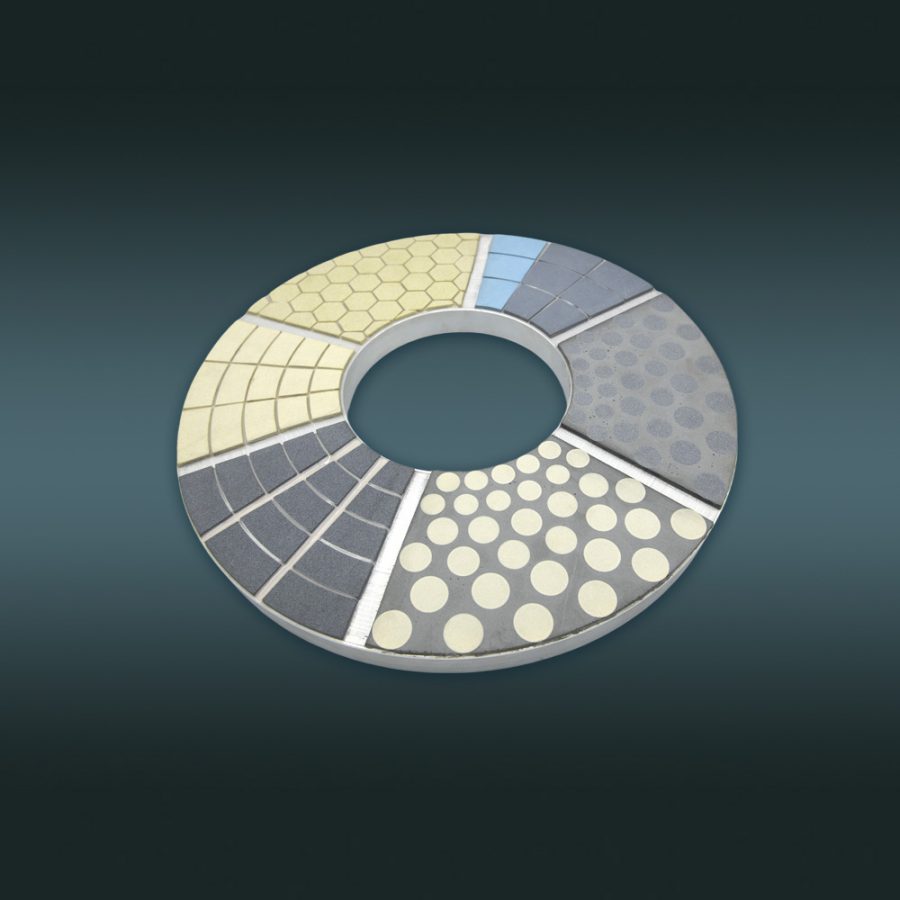

Customization capability: provide grinding wheel particle size, binder, and structural optimization solutions based on the customer's machine model and grinding process.

Full process support: from selection testing to process debugging, the technical team escorts the whole process.