How to Choose the Right Diamond Grinding Tool for Your Mold Manufacturing Needs

Mold manufacturing demands exceptional precision, surface quality, and dimensional stability. From automotive components to consumer electronics and medical devices, molds directly determine the quality of the final product. Selecting the right diamond grinding tool is therefore critical to achieving consistent results, improving efficiency, and controlling production costs. Understanding key factors such as material type, bond selection, grit size, and machining requirements helps manufacturers make informed decisions. The first step in choosing the right diamond grinding tool is identifying the material being processed. Mold materials vary widely, including hardened tool steel, carbide, ceramics, and composite materials. Each material has different hardness, thermal conductivity, and wear characteristics. Diamond grinding tools are particularly effective for hard and brittle materials such as carbide and ceramics, while CBN tools are often preferred for hardened steels. Matching the abrasive type to the workpiece material ensures optimal grinding performance and longer tool life.

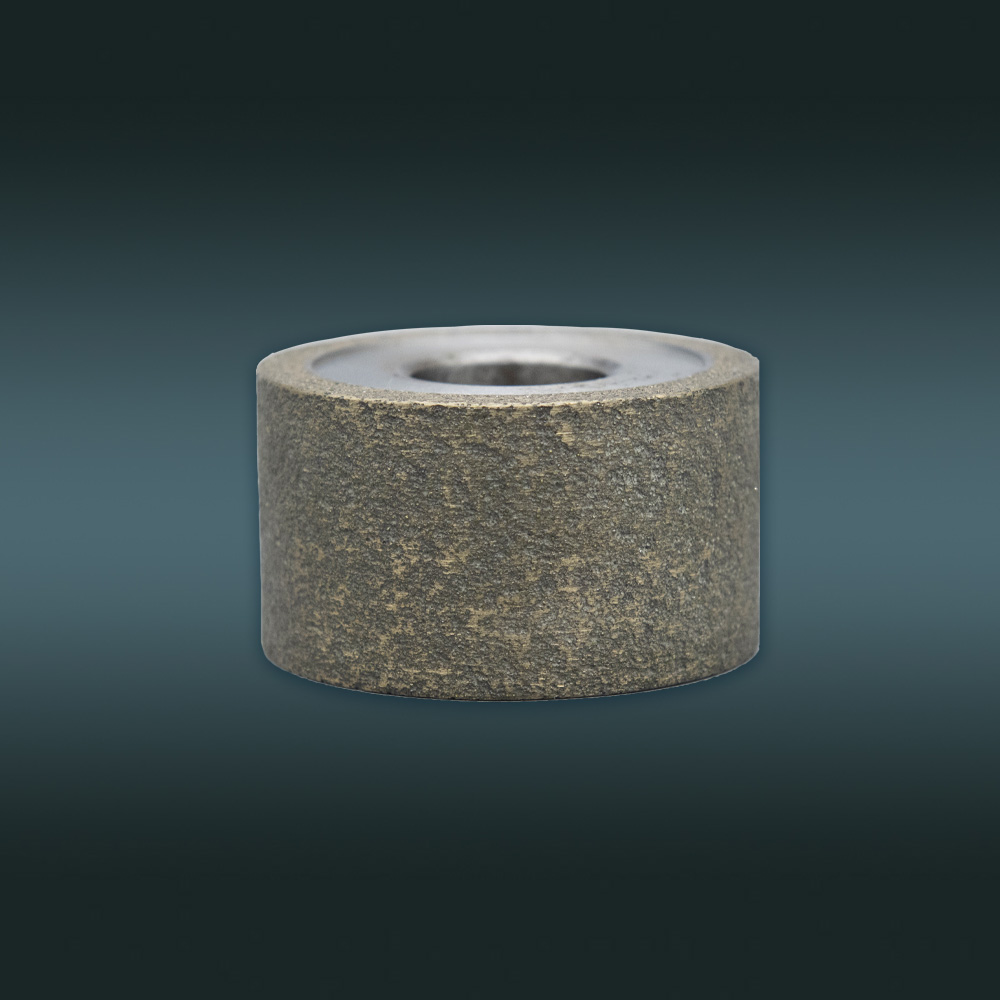

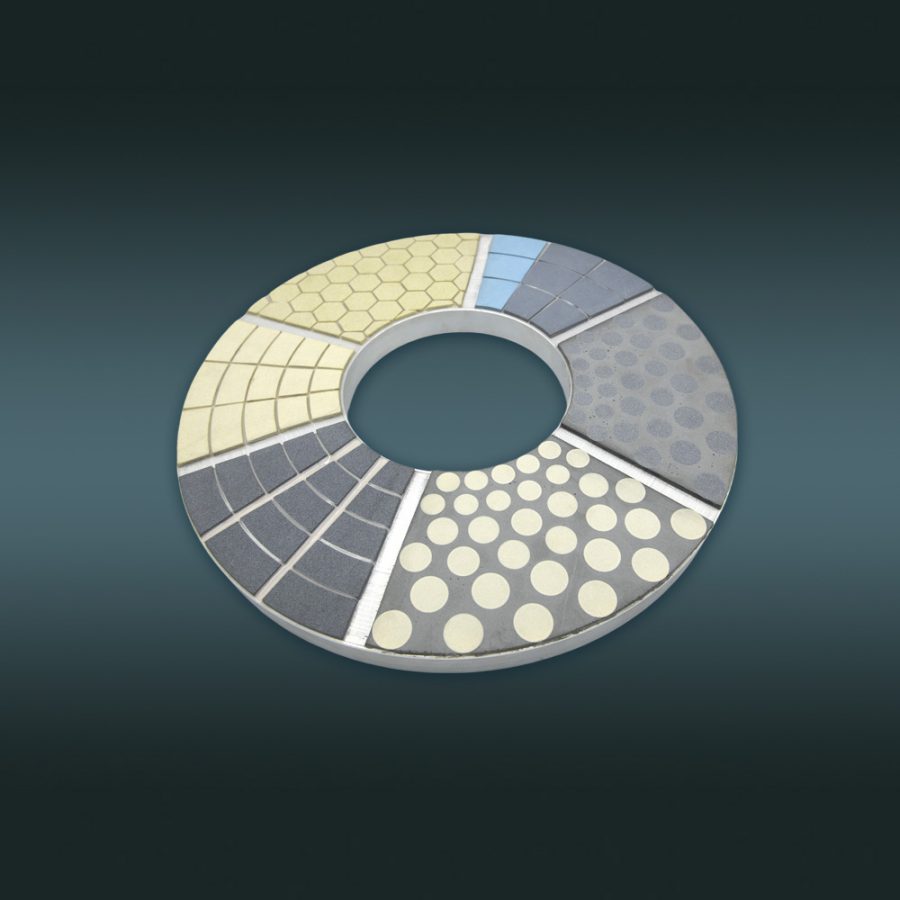

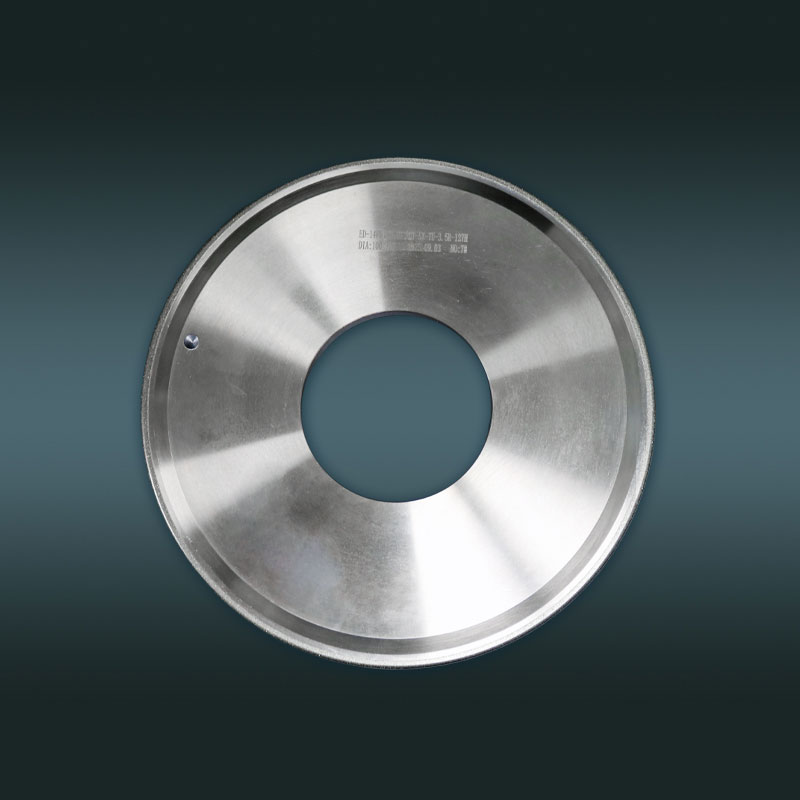

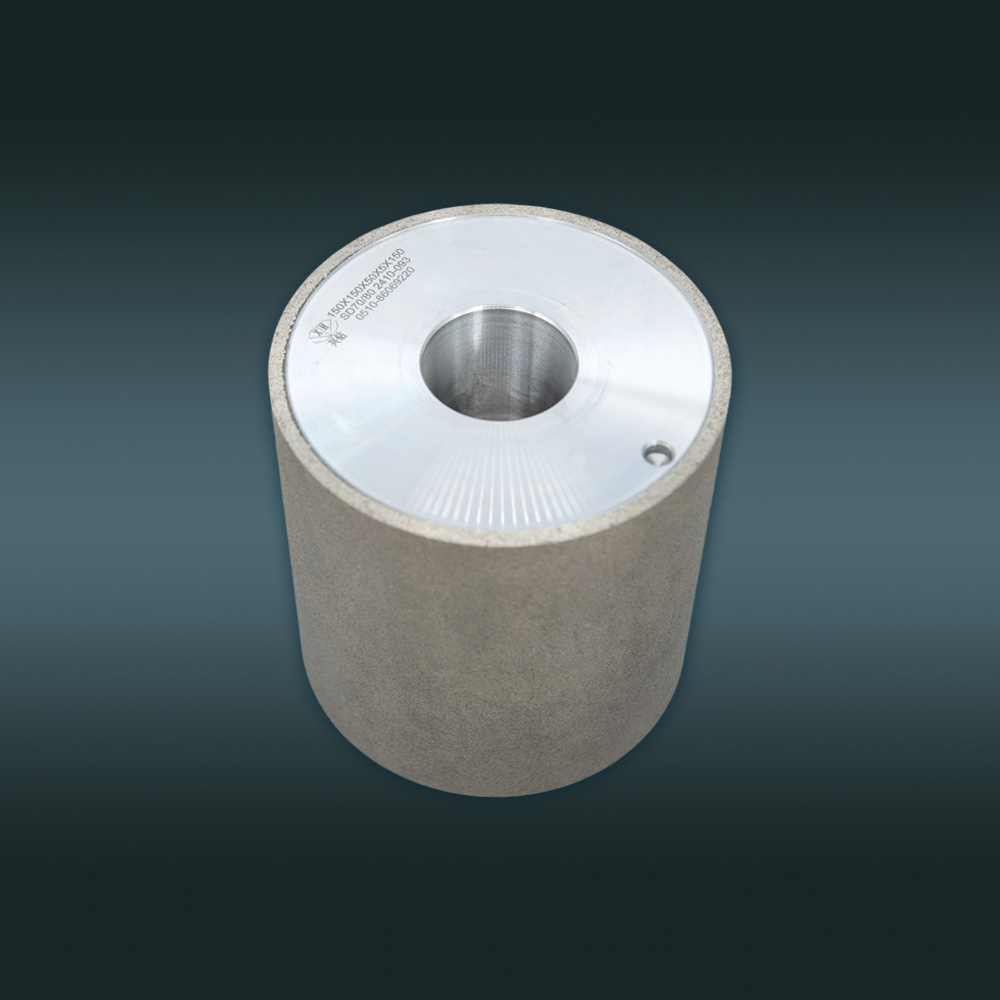

Bond type selection is another critical factor. Diamond grinding tools are typically available in resin bond, metal bond, vitrified bond, and electroplated options. Resin bond tools are ideal for fine finishing and achieving smooth surface quality due to their slight elasticity and good polishing performance. Metal bond tools provide excellent wear resistance and shape retention, making them suitable for rough grinding and long production runs. Vitrified bond tools offer high precision and thermal stability, while electroplated tools are excellent for complex profiles and customized shapes. Grinding stage also influences tool selection. Mold manufacturing usually involves multiple stages, including rough grinding, semi-finishing, and finishing. For rough grinding, a coarser grit size with strong bonding strength is recommended to remove material efficiently. For finishing operations, finer grit sizes are preferred to achieve superior surface finish and tight dimensional tolerances. Selecting the appropriate grit size for each stage improves productivity and prevents unnecessary tool wear.

Wheel shape and profile are equally important in mold manufacturing. Many molds require intricate contours, sharp edges, or detailed cavity structures. Choosing the correct wheel geometry ensures accurate reproduction of these features. Electroplated diamond tools are often used for complex or customized profiles because they maintain precise shapes throughout their service life. Ensuring compatibility between the grinding tool and the mold design enhances machining accuracy. Machine compatibility must also be considered. Grinding tools should match the machine’s speed, power, and rigidity. Improper tool selection can lead to vibration, uneven wear, or reduced accuracy. Checking recommended operating speeds, mounting requirements, and coolant compatibility helps maintain stable performance and extend tool life. A properly matched grinding tool contributes to consistent results and efficient operation.

Thermal management is another key consideration in mold grinding. Excessive heat can cause surface burns, micro-cracks, or dimensional distortion. Selecting a diamond grinding tool with good heat dissipation properties and appropriate bond structure helps reduce thermal damage. Tools with controlled porosity or optimized abrasive exposure improve coolant flow and chip removal, enhancing both surface quality and production stability. Durability and cost efficiency should also guide the decision-making process. While initial tool cost is important, overall performance and lifespan determine long-term value. High-quality diamond grinding tools may have a higher upfront cost but provide better consistency, reduced downtime, and fewer replacements. Evaluating total operating cost rather than purchase price alone leads to more economical choices.

Customization can further optimize mold manufacturing performance. In many cases, standard tools may not fully meet specific requirements. Working with an experienced manufacturer to develop customized diamond grinding tools—tailored in bond type, grit size, concentration, and geometry—ensures that the tool precisely matches production needs. Customized solutions improve efficiency and maintain competitive advantage. In conclusion, choosing the right diamond grinding tool for mold manufacturing involves careful consideration of material type, bond selection, grit size, wheel profile, machine compatibility, and cost efficiency. By evaluating these factors systematically, manufacturers can enhance grinding precision, improve surface quality, and increase overall productivity. The right diamond grinding solution not only ensures high-performance mold production but also supports long-term operational success in precision manufacturing.