How Jiangsu Xingzuan Ensures Superior Quality Control in Grinding Tool Manufacturing

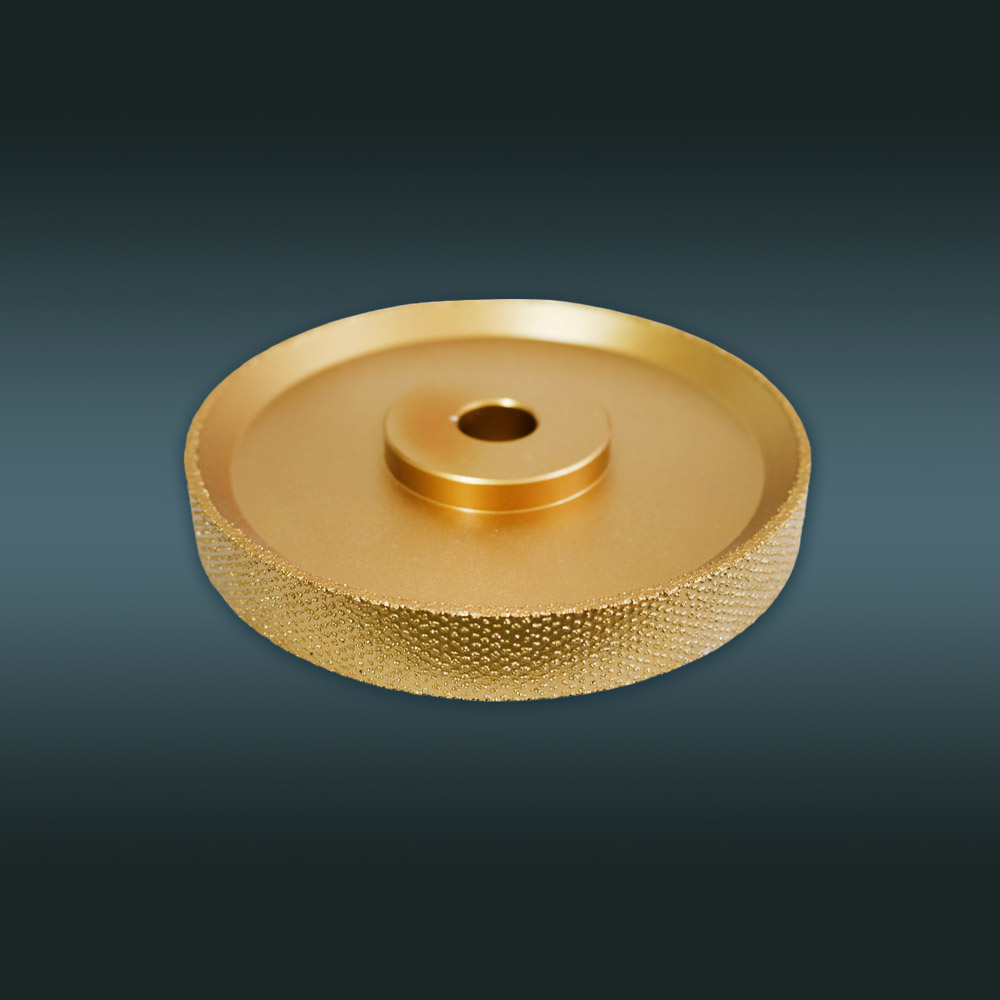

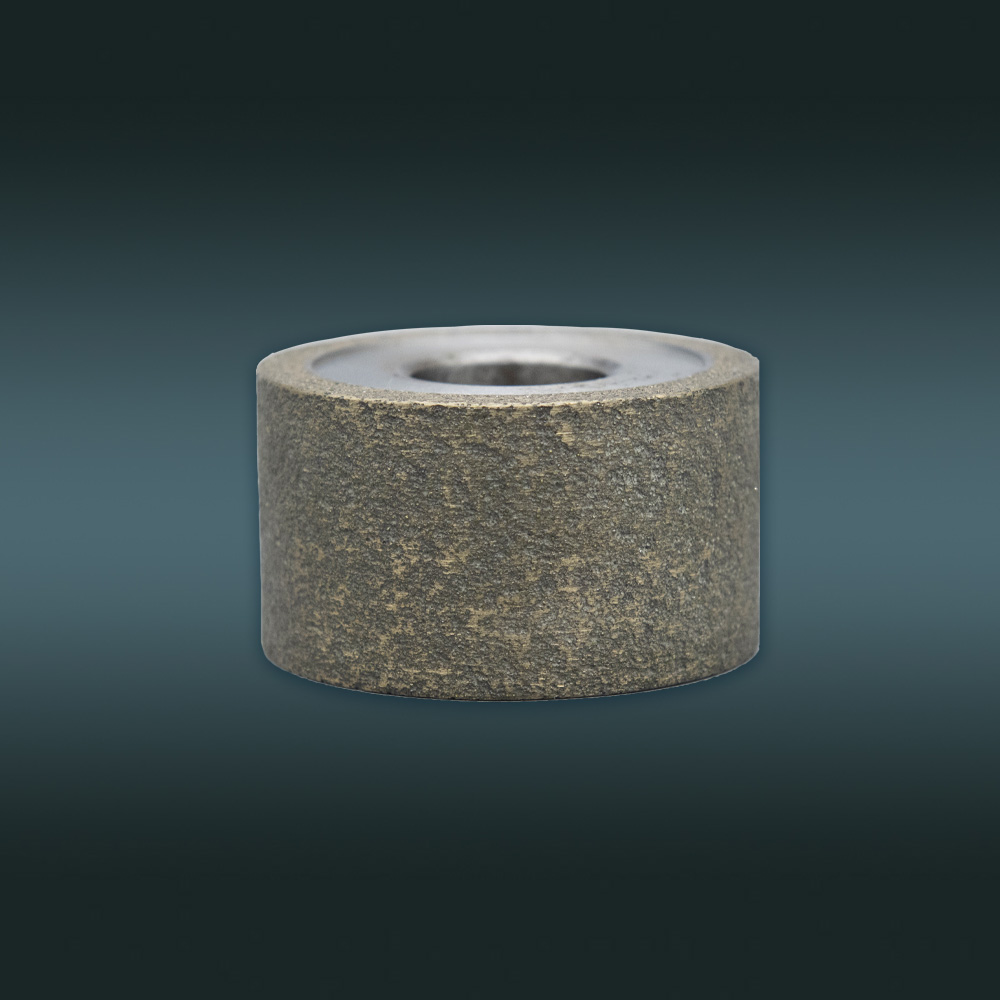

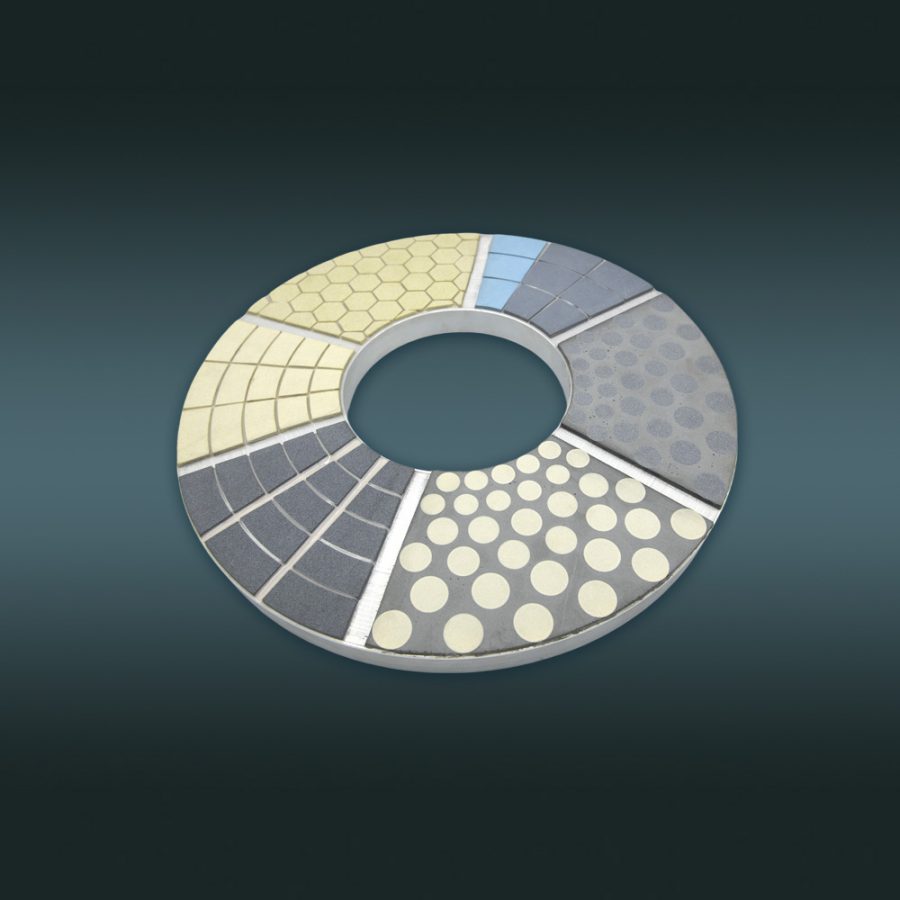

In industries where precision, consistency, and reliability are critical, the quality of grinding tools directly impacts production efficiency and final product performance. As a professional manufacturer specializing in diamond and CBN superhard material tools, Jiangsu Xingzuan Superhard Material Technology Co., Ltd. has established a comprehensive and systematic quality control framework to ensure every grinding tool meets the highest standards. Since its establishment in 2003, the company has consistently focused on quality as the foundation of long-term customer trust and sustainable growth. Superior quality begins with premium raw materials. Jiangsu Xingzuan carefully selects high-grade diamond and cubic boron nitride (CBN) abrasives from reliable sources to ensure stable hardness, uniform particle size, and excellent wear resistance. Bonding materials used in electroplated, resin, metal bronze, vitrified, and brazing series products are also rigorously evaluated for strength, heat resistance, and compatibility with different applications. This strict control at the source ensures that each grinding tool delivers consistent performance from the very beginning.

Jiangsu Xingzuan adopts advanced production technologies and modern manufacturing equipment to maintain high precision and repeatability. Each product series—whether electroplated, resin bond, metal bond, vitrified, or brazed—is manufactured using optimized process parameters developed through years of technical expertise. Key steps such as abrasive distribution, bonding strength control, sintering or brazing temperature management, and dimensional accuracy are closely monitored to prevent defects and ensure product uniformity. The company continuously improves its manufacturing processes by integrating technological upgrades and refining production techniques. This commitment to process excellence enables Jiangsu Xingzuan to meet the increasingly stringent requirements of industries such as aerospace, automotive, medical devices, semiconductors, optical components, and precision ceramics. Quality control at Jiangsu Xingzuan is not limited to final inspection—it is embedded throughout the entire production process. In-process inspections are conducted at multiple stages to detect and correct potential issues early. Parameters such as abrasive concentration, bond integrity, wheel balance, and dimensional tolerances are regularly checked by experienced technicians. By implementing real-time quality monitoring, the company minimizes variations, reduces waste, and ensures stable product quality. This proactive approach significantly enhances production efficiency while maintaining high standards.

Before delivery, every grinding tool undergoes thorough final inspection and testing. Depending on the product type and application, tests may include dimensional accuracy checks, balance testing, bonding strength evaluation, surface quality inspection, and performance simulation under actual working conditions. These tests ensure that each grinding wheel or tool performs reliably in real-world applications. Only products that fully meet Jiangsu Xingzuan’s internal quality standards are approved for shipment. This rigorous final control process ensures that customers receive tools that are ready for immediate use and capable of delivering consistent results. Jiangsu Xingzuan understands that many customers require customized grinding solutions for specific materials, machines, or production processes. Even for customized products, the company applies the same strict quality control standards as for standard products. From design validation and material selection to trial production and testing, every customized solution is carefully reviewed to ensure optimal performance, safety, and durability. This ability to deliver high-quality customized grinding tools further strengthens Jiangsu Xingzuan’s reputation as a reliable long-term partner.

A skilled and experienced technical team is at the core of Jiangsu Xingzuan’s quality assurance system. Engineers and technicians with deep knowledge of superhard materials continuously analyze product performance and customer feedback. This information is used to improve designs, refine processes, and enhance overall product quality. The company also emphasizes continuous improvement, regularly reviewing internal quality standards and aligning them with evolving industry requirements and technological advancements. Superior quality control is not a single step but a comprehensive system built on strict material selection, advanced manufacturing processes, continuous inspection, and rigorous testing. Through its well-established quality management framework, Jiangsu Xingzuan ensures that every diamond and CBN grinding tool delivers exceptional precision, durability, and reliability. By choosing Jiangsu Xingzuan, customers gain a trusted partner committed to quality excellence and long-term success in precision manufacturing.