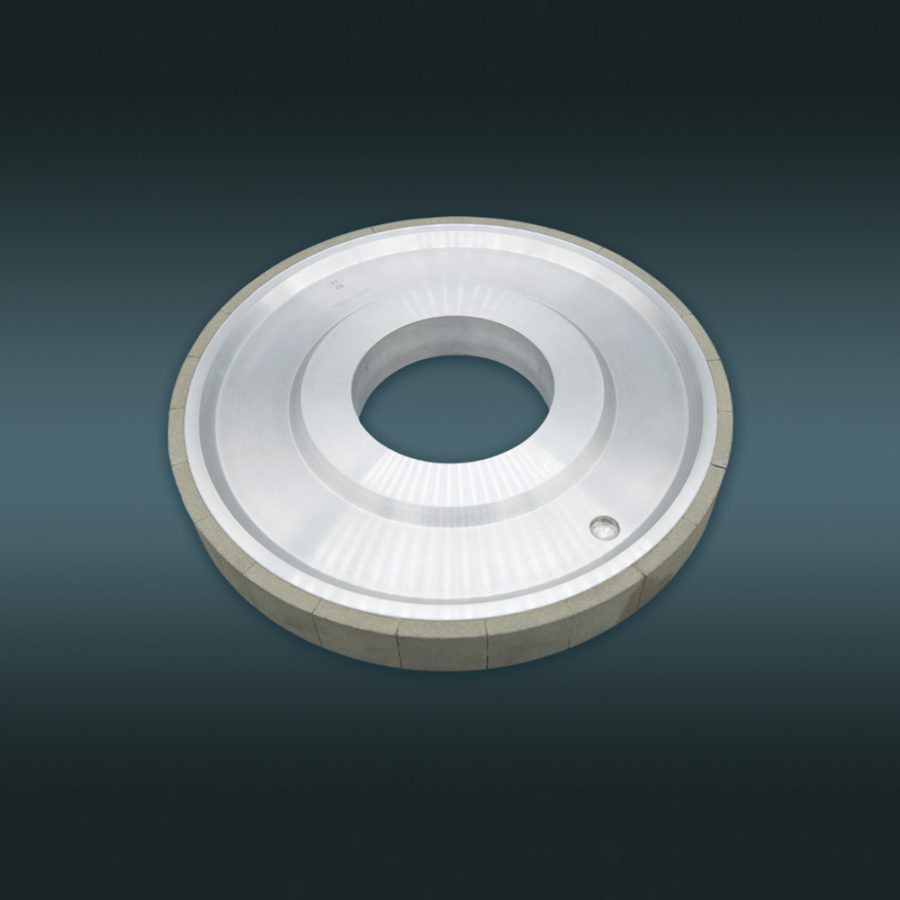

Vitrified Bond Diamond Grinding Wheel

-

Used for grinding electronic packaging substrates, optical components, and dental restoration materials made of alumina ceramic materials.

High hardness, strong wear resistance, good sharpness, and high precision.

Minimum Order Quantity: 10pcs

Net Weight: 1.3KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

14A1 vitrified bond diamond grinding wheel is a tool used for grinding and processing, mainly for processing high hardness and brittleness materials such as hard alloys, ceramics, glass, magnetic materials, diamond composites, PCD/CBN cutting tools, etc.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | 120/140 |

| Model Number | 14A1 |

| Outside Diameter | 180mm |

| Net Weight | 1.3KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for polishing PCD, PCBN and other superhard cutting tools.

- Used for grinding hard alloy materials such as tungsten steel, it can efficiently remove materials.

- Used for processing ceramic products such as industrial ceramics and ceramic cutting tools.

- Used for grinding and processing semiconductor silicon wafers and solar silicon wafers.

- Used for cutting, grinding, and polishing of gemstones and crystals.

- Used for grinding processing of rare earth magnetic materials, etc.

Competitive Advantage

- High grinding efficiency, able to quickly remove materials and improve processing efficiency.

- Not easy to generate heat and block, can effectively reduce heat accumulation, and the porosity of the grinding wheel is high, making it less likely for debris to block the grinding wheel.

- Strong wear resistance, and abrasive particles are not easily detached.

- Good chemical stability, not prone to chemical reactions with workpiece materials, ensuring grinding effectiveness and workpiece quality.

- High precision is beneficial for precise control of machining dimensions and shape accuracy.