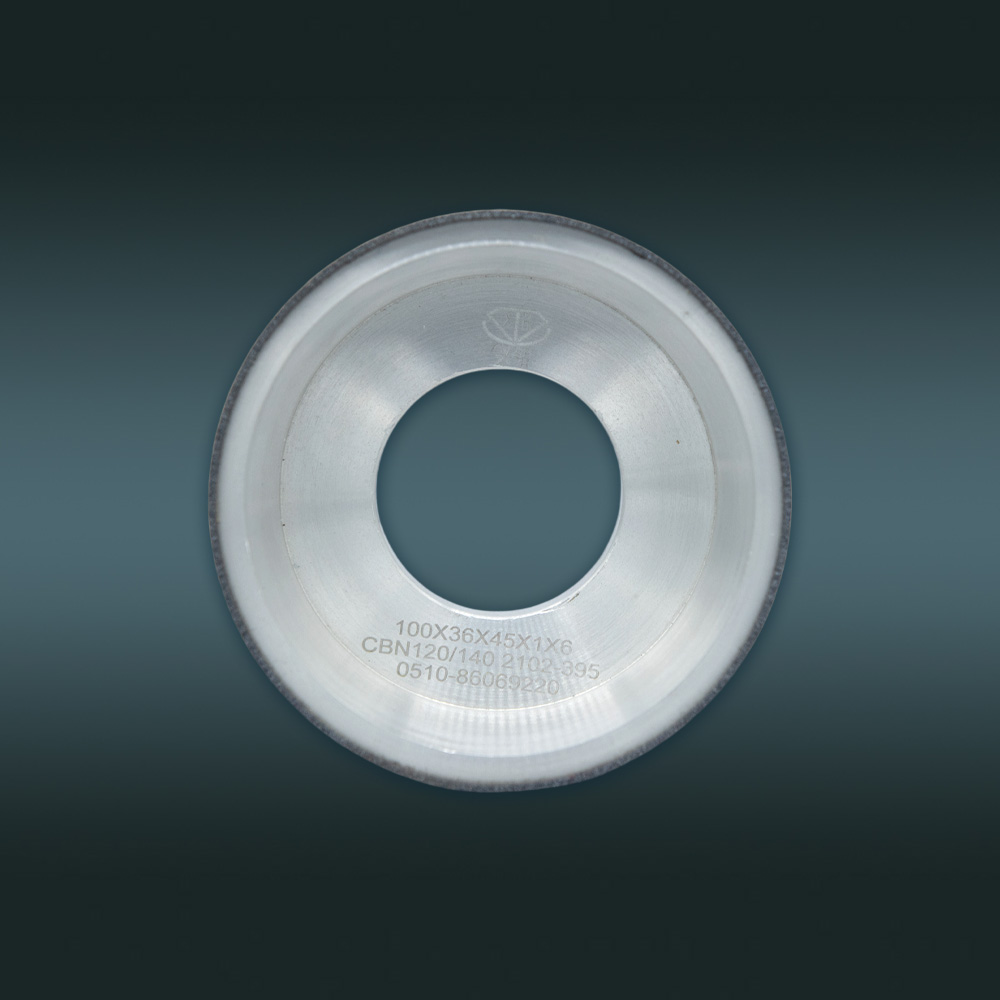

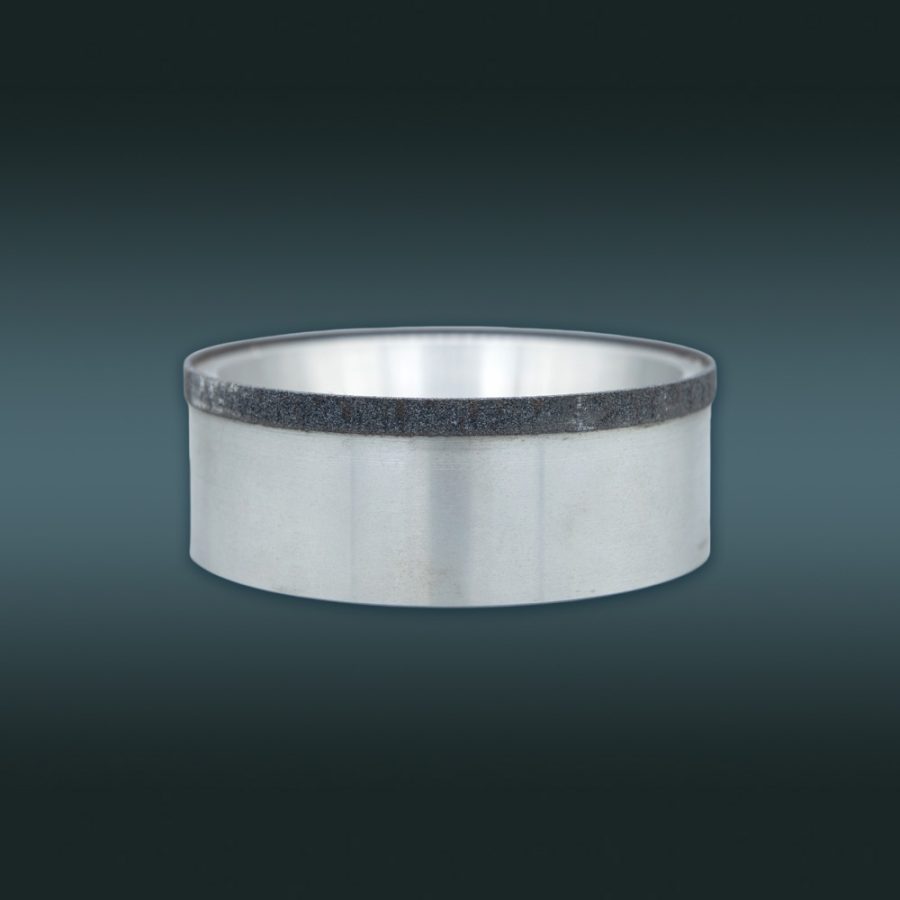

5A2 Vitrified Bond CBN Grinding Wheel

-

Suitable for grinding hard alloys, high-speed steel, alloy steel, quenched steel, and titanium alloys.

High hardness, good toughness, strong cutting ability, sharpness, and strong chemical inertness.

Minimum Order Quantity: 30pcs

Net Weight: 490g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

5A2 vitrified CBN grinding wheel is mainly used for high-precision grinding processing, with strong grinding force and can maintain good grinding efficiency. Suitable for processing metal materials such as high manganese steel, high chromium nickel molybdenum alloy steel, chilled cast iron, various quenched steels, and cast iron.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | CBN |

| Bond | Vitrified bond |

| Abrasive Grit Size | 120/140 |

| Model Number | 5A2 |

| Specification | 100*36*45*1*6 |

| Outside Diameter | 100mm |

| Hole | 45mm |

| Total Thickness | 36mm |

| Net Weight | 490g |

| Minimum Order Quantity | 30pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding shaft components such as crankshafts and camshafts in automotive engines.

- Used for grinding automotive gears, improving gear accuracy and surface roughness, and reducing transmission noise.

- Grinding key components such as turbine blades and compressor blades for aircraft engines.

- Used for grinding various high-speed steel cutting tools, hard alloy cutting tools, etc.

- Grinding various high hardness alloy steels, quenched steels and other steel materials, such as high manganese steel, high chromium nickel molybdenum alloy steel, etc.

- Grinding titanium alloy to avoid burns and cracks.

Competitive Advantage

- High hardness, good toughness, strong cutting ability, and high sharpness.

- Good high temperature resistance and thermal stability, there will be no sticking phenomenon when grinding heat sensitive metal materials such as quenched steel.

- Strong chemical inertness, not easily reacting with iron group elements.

- Good thermal conductivity, can reduce thermal deformation of workpieces, suitable for grinding materials with low thermal conductivity and wear-resistant cast iron and titanium alloy materials.