Maximizing Efficiency with Metal Bronze Series Grinding Wheels

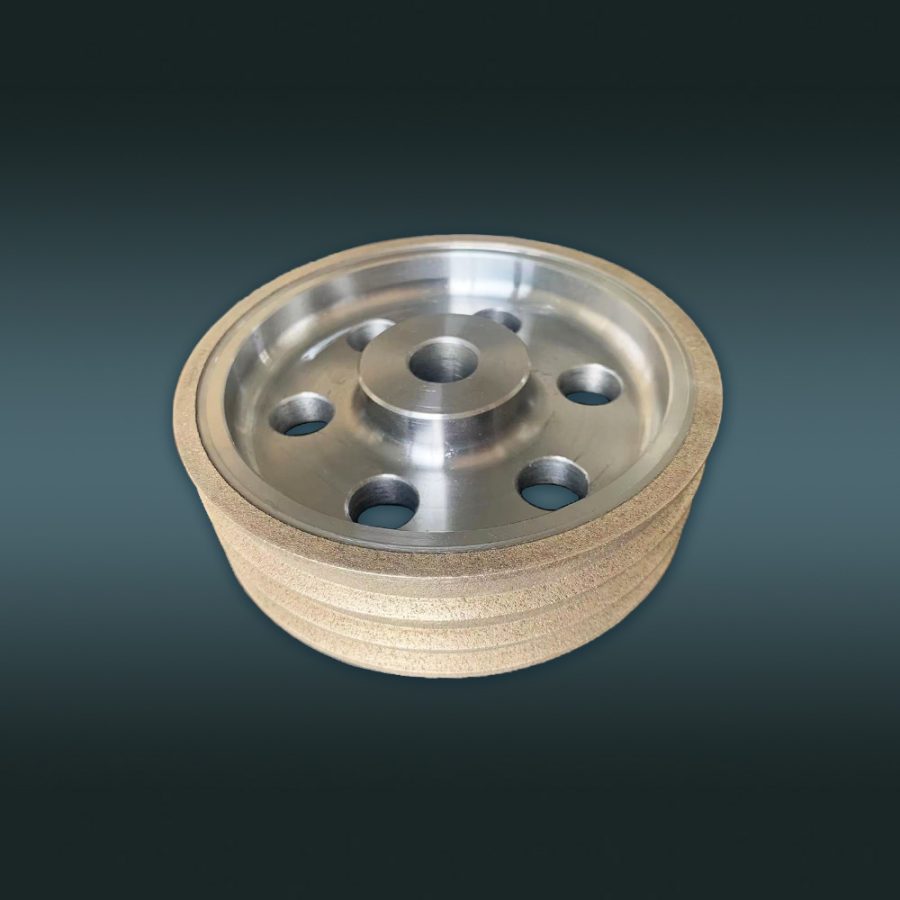

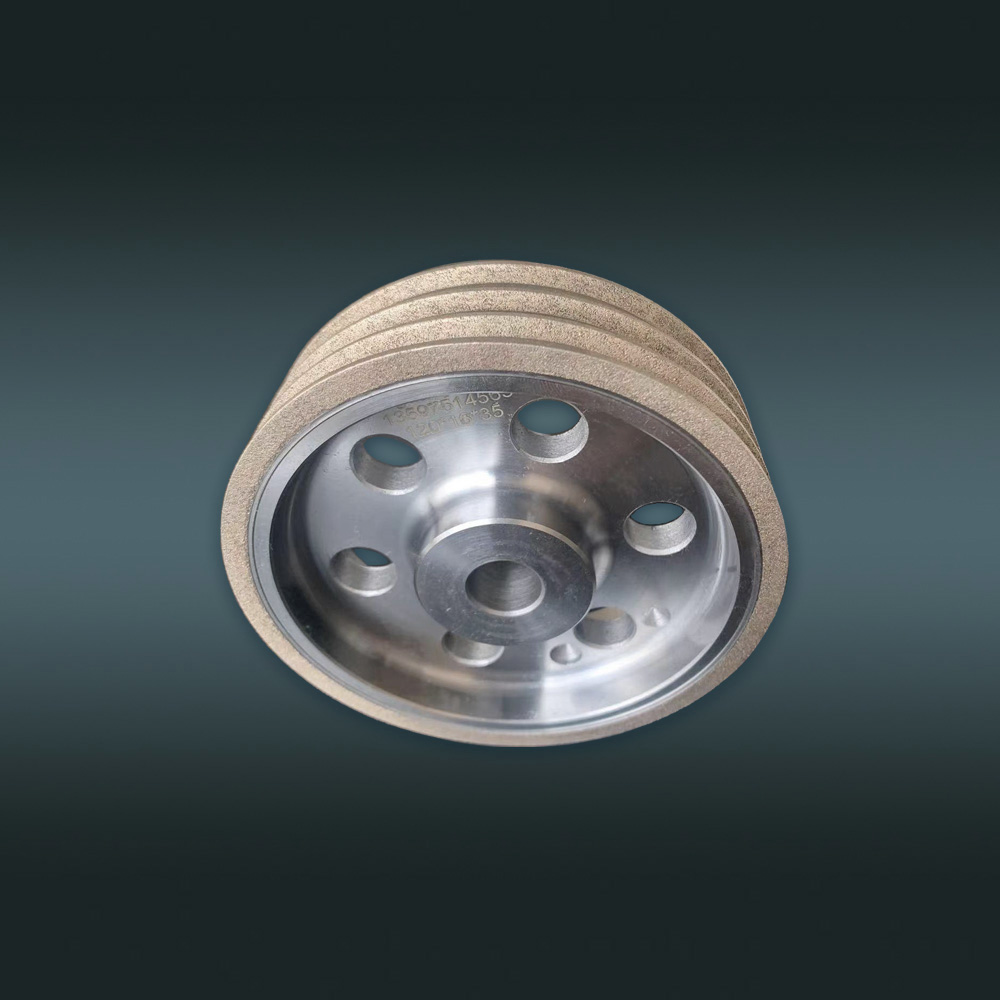

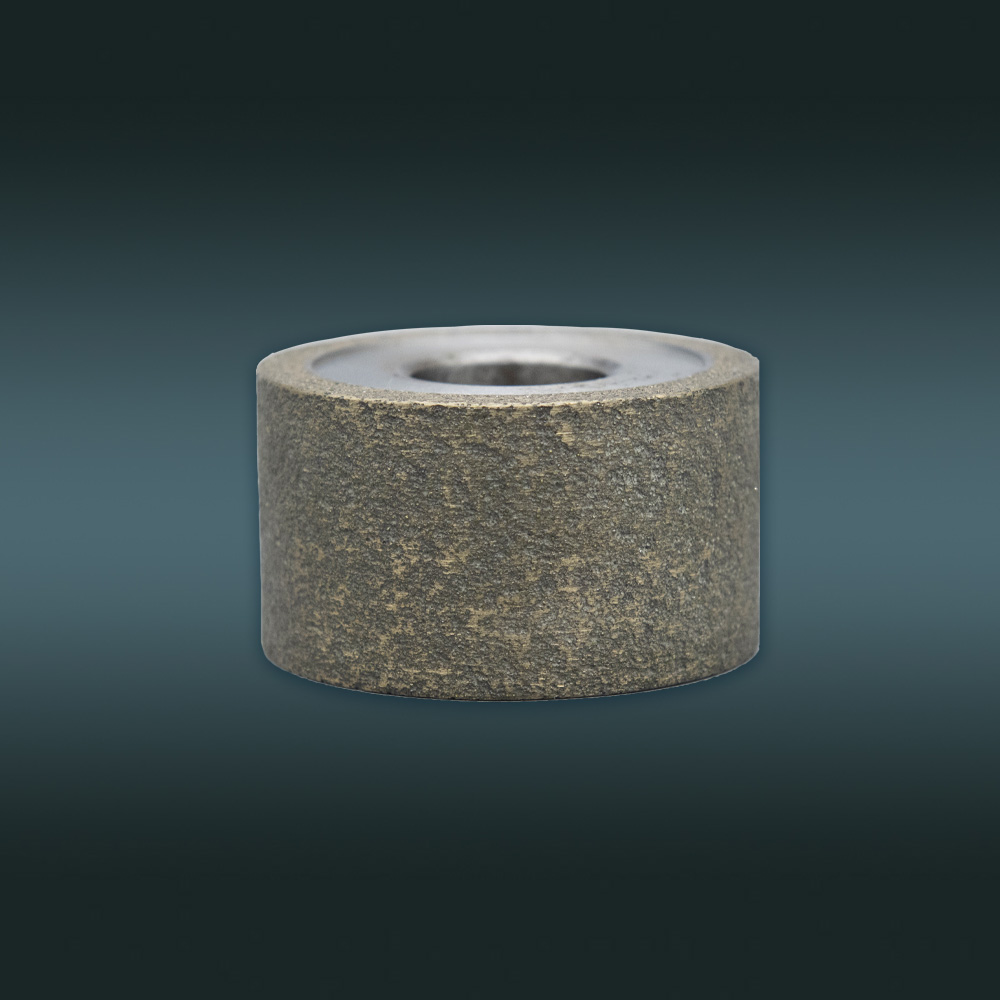

Metal bronze series grinding wheels are widely valued in precision machining for their durability, stability, and ability to maintain consistent performance under demanding conditions. Designed with a strong metal bond, typically based on bronze alloys, these grinding wheels are especially suitable for applications that require high material removal rates, long tool life, and excellent dimensional accuracy. By understanding their advantages and proper applications, manufacturers can significantly maximize efficiency in their grinding processes. One of the primary strengths of metal bronze series grinding wheels is their exceptional wear resistance. The metal bond securely holds diamond or CBN abrasive grains in place, allowing the wheel to withstand prolonged grinding operations without rapid wear. This durability reduces the frequency of wheel replacement, minimizing downtime and improving overall production efficiency, particularly in continuous or high-volume manufacturing environments.

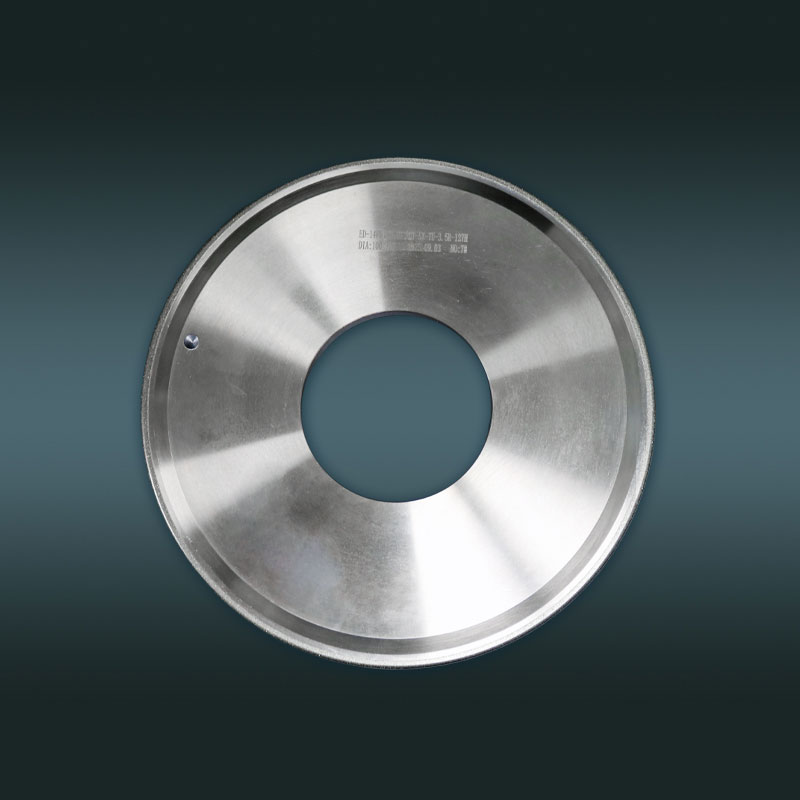

Metal bronze grinding wheels are known for their outstanding shape retention. Even under high pressure and extended use, the rigid metal bond maintains the original wheel profile. This ensures stable grinding accuracy and consistent results throughout the machining process. For applications such as precision ceramics, carbide tools, glass processing, and advanced composite materials, maintaining precise dimensions is critical to product quality and process reliability. Another important efficiency advantage is the ability of metal bronze series grinding wheels to handle hard and abrasive materials effectively. Materials that are difficult to machine using conventional grinding wheels can be processed more efficiently with metal bond tools. Their strong bonding structure allows aggressive grinding while maintaining control, enabling faster material removal without sacrificing accuracy.

Thermal stability is also a key factor in maximizing efficiency. Metal bronze grinding wheels perform reliably under elevated temperatures, making them suitable for heavy-duty grinding applications. When combined with proper cooling and process parameters, they help reduce thermal deformation and surface damage on the workpiece, contributing to higher yields and fewer rejected parts. Metal bronze series grinding wheels also offer excellent consistency over long production runs. Because the abrasive grains are firmly retained, the wheel’s cutting performance remains stable, reducing fluctuations in surface finish and dimensional accuracy. This consistency simplifies process control, lowers the need for frequent adjustments, and supports repeatable results in automated or precision machining systems.

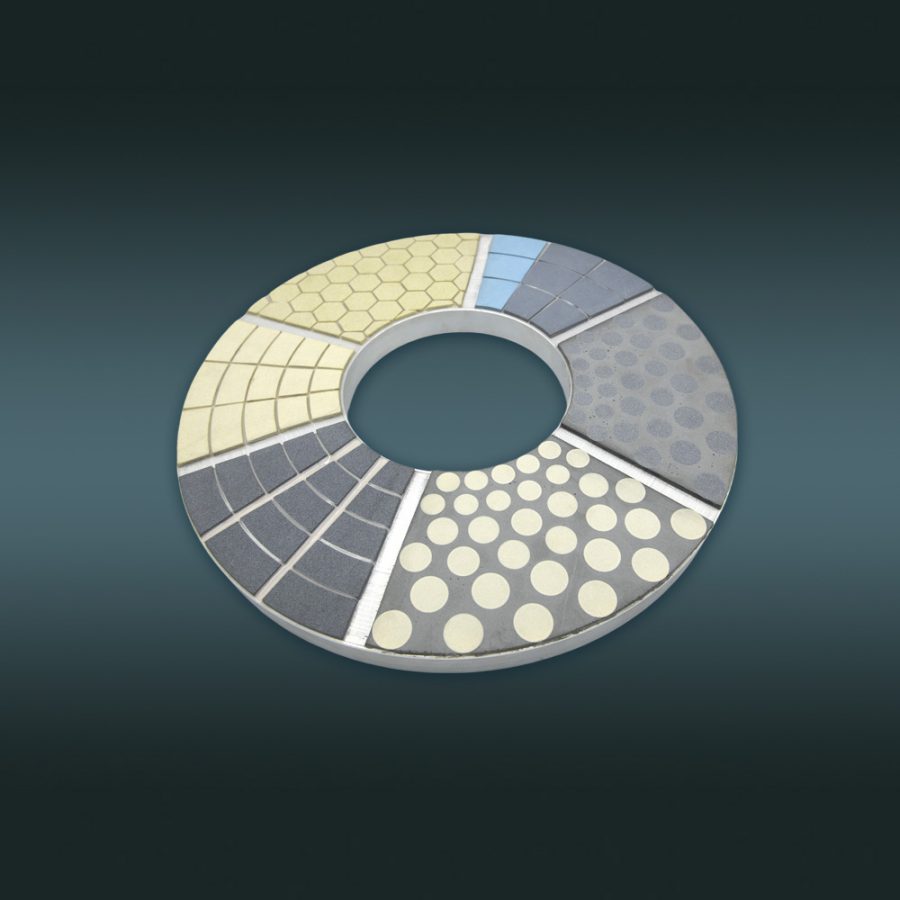

From a cost-efficiency perspective, metal bronze grinding wheels provide long-term value. Although the initial investment may be higher compared to some other bond types, their extended service life and reduced maintenance requirements result in lower overall operating costs. Fewer wheel changes and less machine downtime translate directly into higher productivity and improved return on investment. Customization further enhances the efficiency of metal bronze series grinding wheels. By adjusting abrasive type, grain size, bond composition, and wheel geometry, manufacturers can tailor these tools to specific materials and applications. Customized solutions allow optimal grinding performance, reduced cycle times, and improved surface quality for specialized processing needs.

Proper application and process optimization are essential to fully maximize the benefits of metal bronze grinding wheels. Selecting the right wheel specification, using appropriate machine rigidity, and applying effective cooling methods ensure stable performance and prevent excessive grinding forces. When used correctly, metal bronze wheels deliver a balance of power, precision, and reliability. In conclusion, metal bronze series grinding wheels are a powerful solution for maximizing efficiency in precision grinding applications. Their superior wear resistance, shape retention, thermal stability, and long service life make them ideal for processing hard and demanding materials. By integrating metal bronze grinding wheels into optimized grinding processes, manufacturers can achieve higher productivity, consistent quality, and long-term operational efficiency in modern manufacturing environments.