Understanding the Differences Between Resin, Metal, and Electroplated Grinding Wheels

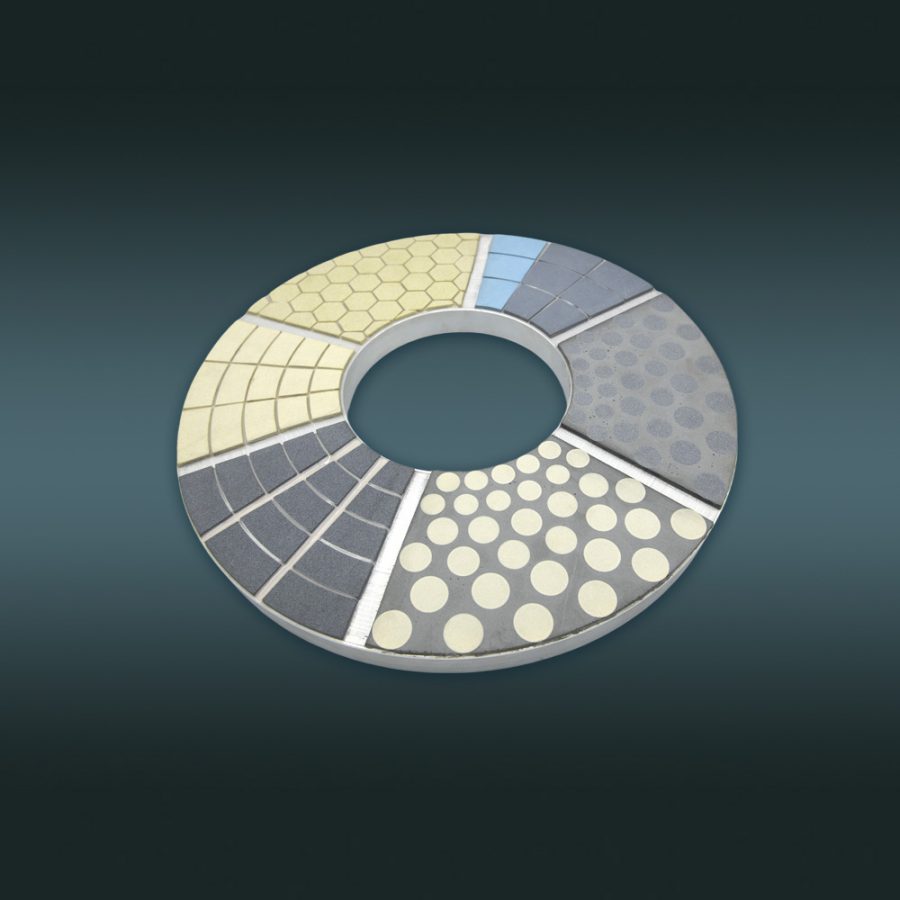

Grinding wheels play a critical role in modern precision manufacturing, and selecting the right type directly affects efficiency, surface quality, and tool life. Among the most commonly used superhard grinding wheels are resin bond, metal bond, and electroplated grinding wheels. Each type has distinct structural characteristics, performance advantages, and ideal application scenarios. Understanding the differences between these grinding wheels helps manufacturers choose the most suitable solution for their specific processing needs.

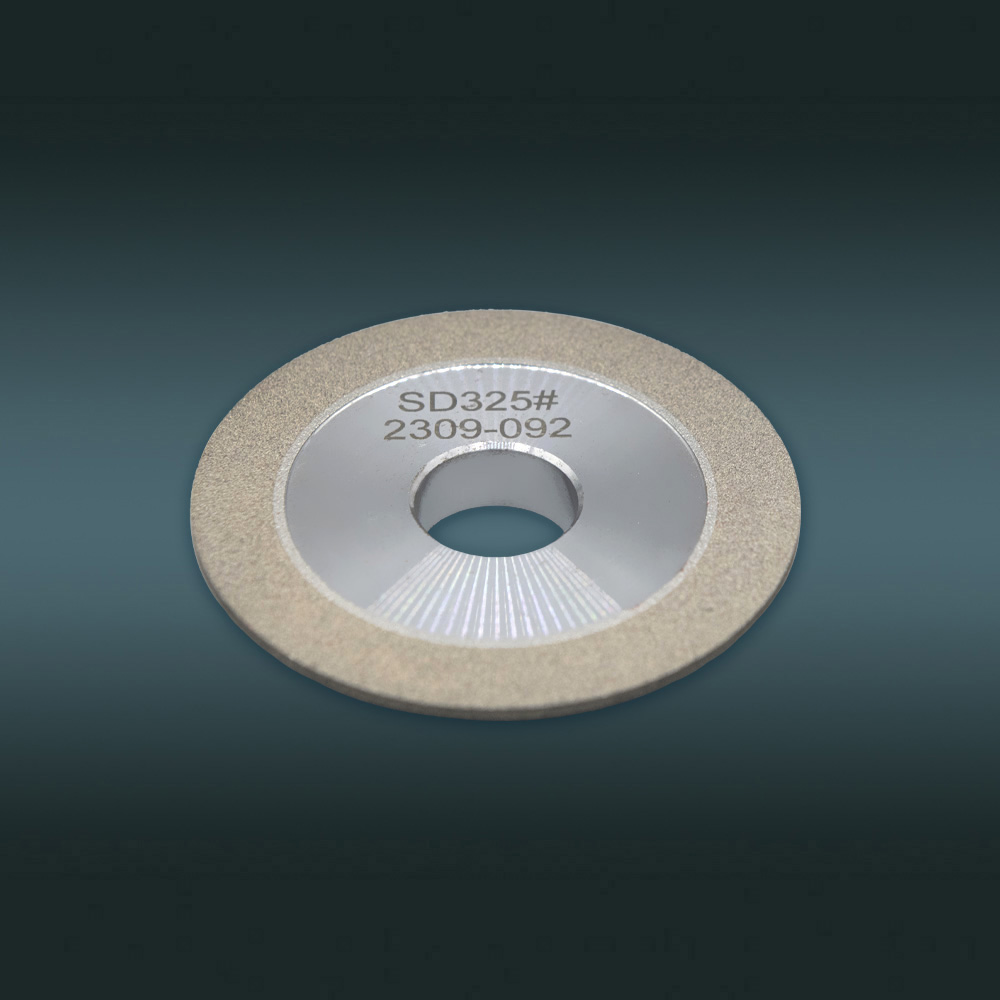

Resin bond grinding wheels are widely used due to their versatility and excellent finishing performance. In these wheels, diamond or CBN abrasive grains are bonded using a resin-based material. This structure provides a relatively elastic bond, allowing the wheel to absorb vibration during grinding. As a result, resin bond wheels deliver smooth cutting action and superior surface finishes, making them ideal for precision grinding, polishing, and finishing operations. One of the main advantages of resin bond grinding wheels is their ability to produce fine surface quality with minimal damage to the workpiece. They are commonly used in industries such as mold manufacturing, optical components, precision ceramics, and semiconductor processing. However, resin bond wheels generally have lower heat resistance and wear faster under heavy loads, which means they are better suited for light to medium grinding rather than aggressive material removal.

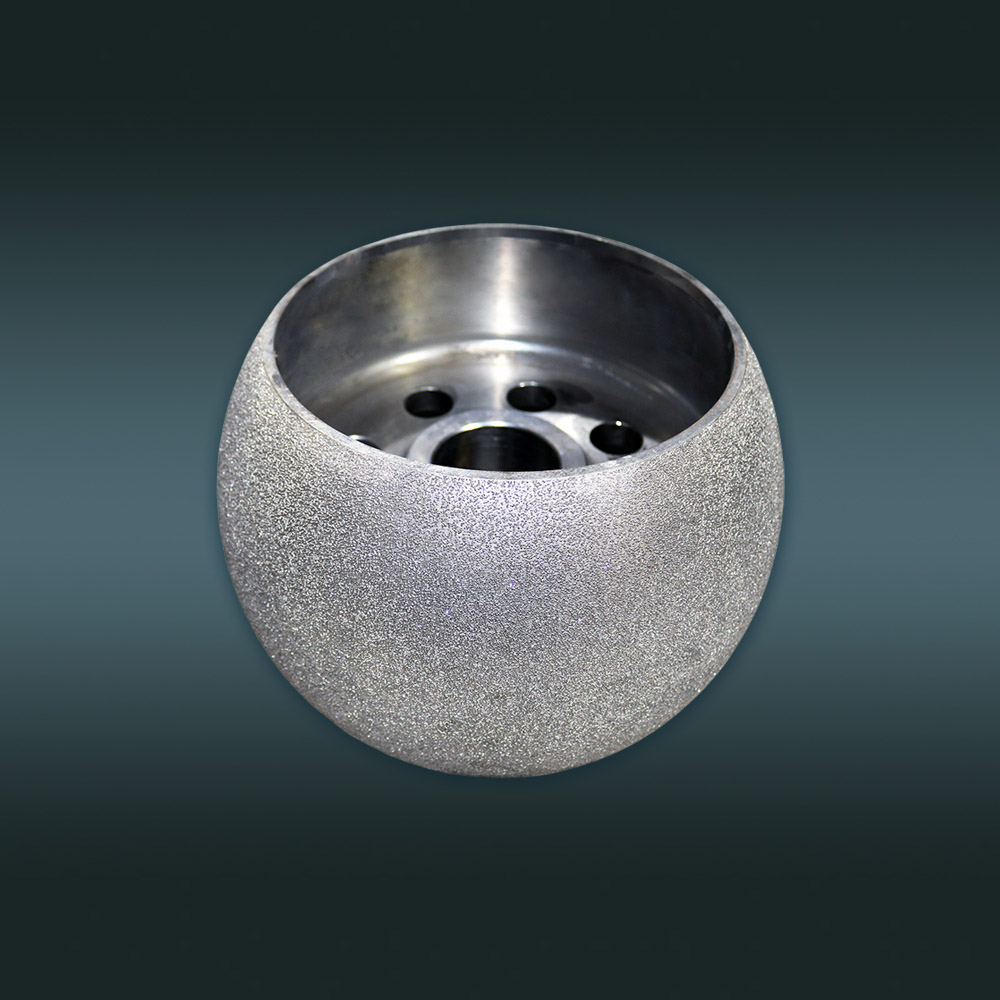

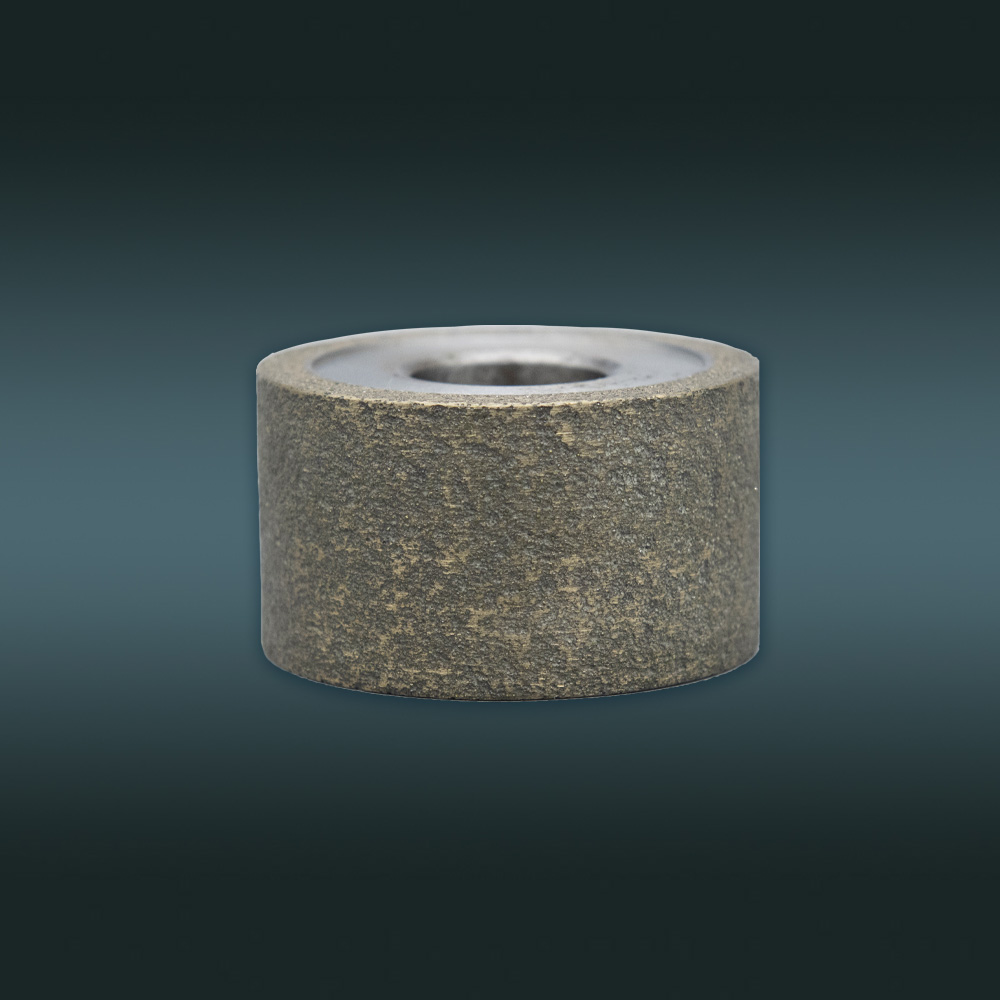

Metal bond grinding wheels are designed for durability and long service life. In this type of wheel, abrasive grains are firmly held in a metal matrix, such as bronze or other metal alloys. This strong bond provides excellent wear resistance, allowing the wheel to maintain its shape even under high pressure and extended use. Metal bond wheels are particularly effective for grinding hard and brittle materials that require stable and consistent performance. Due to their strong bonding structure, metal bond grinding wheels are commonly used in applications such as precision ceramics, glass, stone, carbide materials, and advanced composite materials. They offer excellent shape retention and dimensional accuracy, which is critical for high-precision machining. However, because the abrasive grains are held more rigidly, metal bond wheels may generate higher grinding forces and are less forgiving than resin bond wheels, requiring proper machine rigidity and process control.

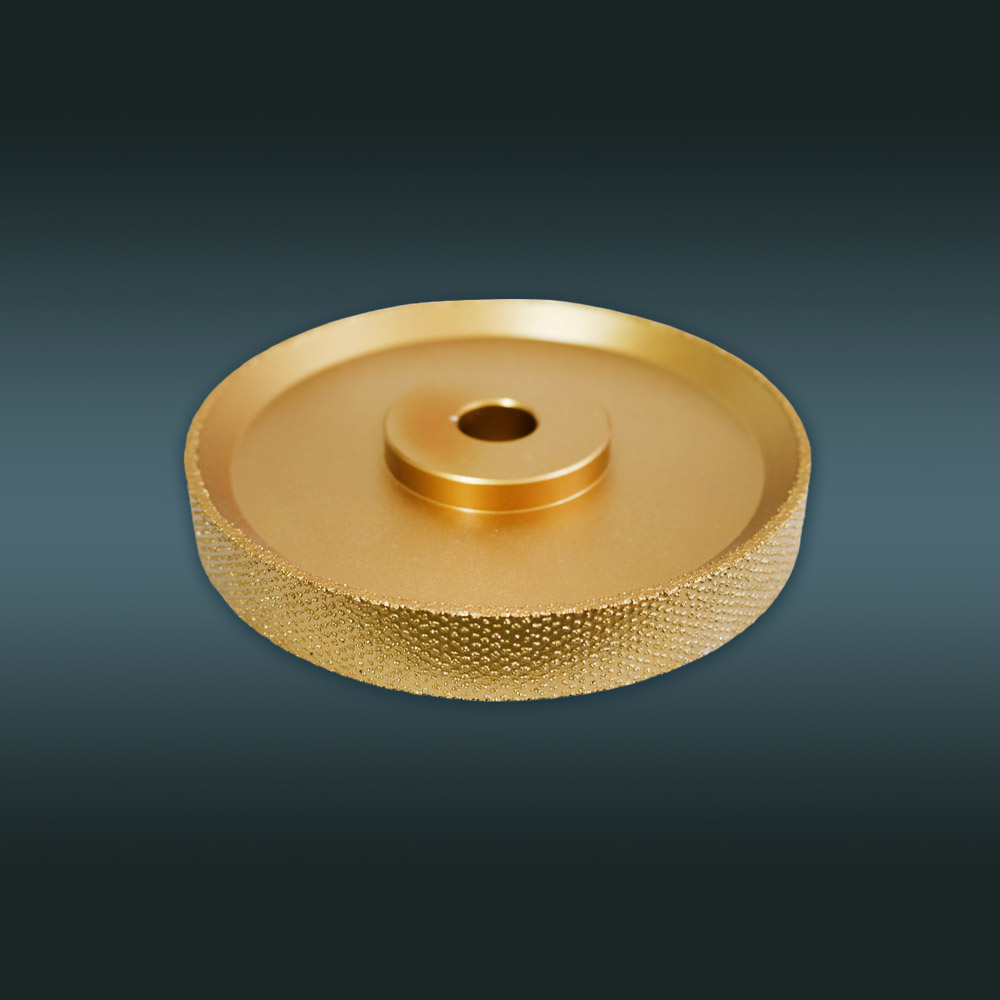

Electroplated grinding wheels differ significantly from resin and metal bond wheels in both structure and performance. Electroplated wheels use an electrochemical process to bond a single layer of diamond or CBN abrasive grains directly onto the wheel body. This creates a highly exposed cutting surface where each abrasive grain can perform efficiently. As a result, electroplated wheels deliver aggressive cutting action and high material removal rates. One of the key advantages of electroplated grinding wheels is their exceptional precision and consistency. Because the abrasive layer is thin and firmly bonded, the wheel maintains its exact shape throughout its service life. This makes electroplated wheels ideal for applications requiring complex profiles, tight tolerances, and customized tool shapes. They are widely used in aerospace, medical devices, automotive components, mold manufacturing, and optical processing.

Electroplated wheels also offer excellent heat dissipation and chip removal due to their open abrasive structure. This reduces thermal damage to the workpiece and allows for stable grinding performance, even on hard-to-machine materials. However, since electroplated wheels typically have only one abrasive layer, they cannot be dressed or reconditioned. Once the abrasive layer is worn, the wheel must be replaced. When comparing these three types, each serves a distinct purpose. Resin bond grinding wheels excel in achieving fine surface finishes and smooth grinding results. Metal bond wheels offer superior durability, shape retention, and long tool life for demanding applications. Electroplated grinding wheels provide unmatched precision, sharp cutting performance, and customization flexibility for specialized machining tasks.

In conclusion, there is no single grinding wheel that fits all applications. The choice between resin, metal, and electroplated grinding wheels depends on factors such as material type, required surface finish, machining accuracy, production volume, and cost considerations. By understanding the differences between these grinding wheel types, manufacturers can optimize their grinding processes, improve product quality, and achieve greater efficiency in modern precision manufacturing.