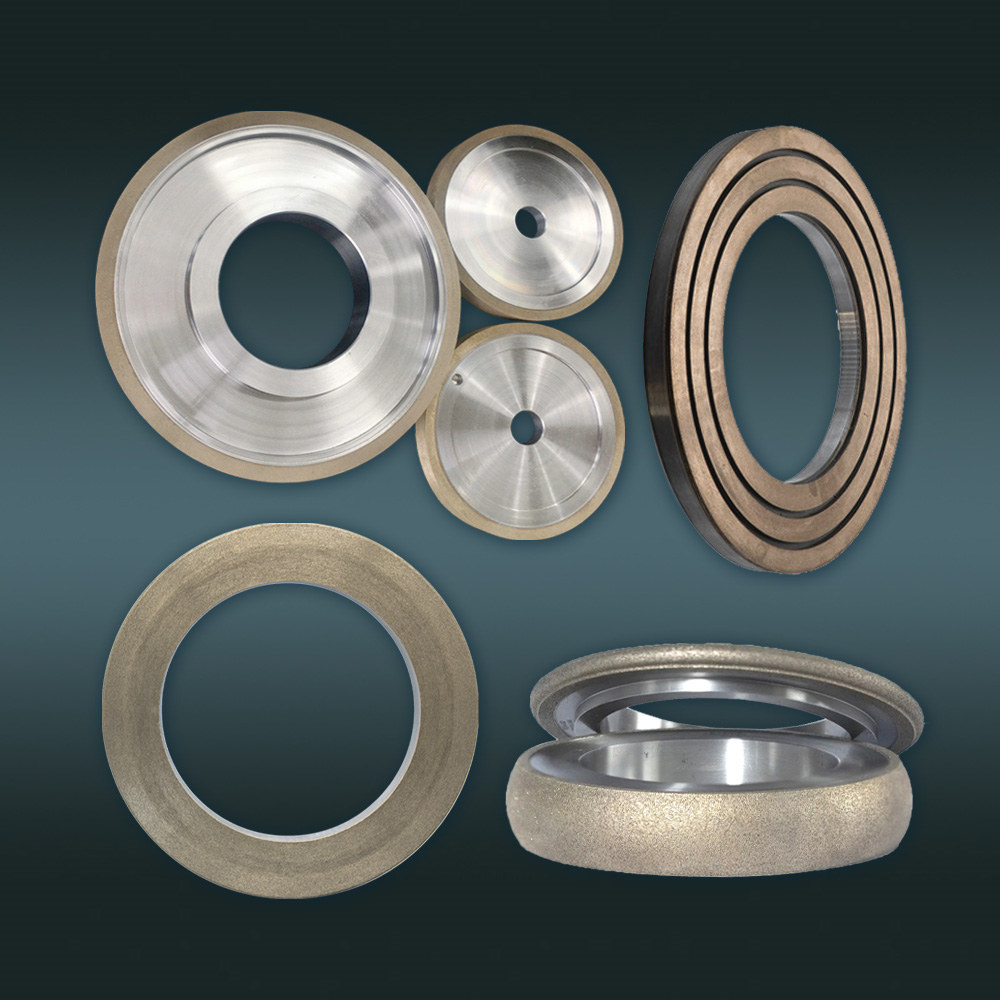

Metal Diamond Grinding Wheels for Steel Mill Rolls

-

Custom-made for steel mill rolls.

Excellent wear resistance, long life, excellent shape retention, and excellent thermal conductivity.

Minimum Order Quantity: 10pcs

Net Weight: 8KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

This Metal diamond grinding wheel is essential and long-lasting tools for steel mill roll machining.It offers long life, excellent wear resistance, and strong shape retention. It is suitable for rough grinding with large allowances and heavy loads, machining large numbers of rolls after a single profile repair, and profile grinding requiring high precision.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Metal |

| Abrasive Grit Size | 100/120 |

| Model Number | 14A1 |

| Specification | |

| Net Weight | 8KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Suitable for rough machining and efficient roughing of rolls. When rolls are severely worn and require significant stock removal (several millimeters), bronze grinding wheels, with their strong load-bearing capacity and long life, can efficiently complete the task without significant shape loss.

- Suitable for batch repair of high-precision profiles. For rolls requiring stringent profile accuracy (such as specific curves and grooves), bronze grinding wheels' unparalleled shape retention makes them the preferred choice. Once repaired, hundreds of rolls can be reliably processed without frequent profile retouching.

- Suitable for texturing processes requiring the utmost in life and stability. Large steel mills demand stable, continuous, and high-volume roll texturing lines. The long life and repairability of bronze diamond grinding wheels minimize downtime for wheel replacement, ensuring consistent product surface quality.

Competitive Advantage

1. It boasts extremely high bond strength. The sintered bronze bond provides a strong grip on the diamond, making it extremely wear-resistant and long-lasting.

2. It has excellent shape retention. Due to its integral sintering, the grinding wheel maintains its original shape and precision throughout its lifespan, making it particularly suitable for high-precision form grinding.

3. It is dressable and resharpenable, a key difference from electroplated grinding wheels. Bronze grinding wheels can be dressed and sharpened after wear or before use using specialized dressing tools (such as silicon carbide grinding stones and diamond rollers). Resharpening can also remove the bond, allowing the abrasive grains to protrude and restore their sharpness.

4. It has excellent thermal conductivity. The bronze metal bond is an excellent thermal conductor, helping to quickly conduct heat away from the grinding zone, thereby reducing the grinding point temperature and minimizing the risk of roller burn.

5. It has a high load-bearing capacity, making it suitable for heavy-load, large-residue rough grinding and high-efficiency grinding.