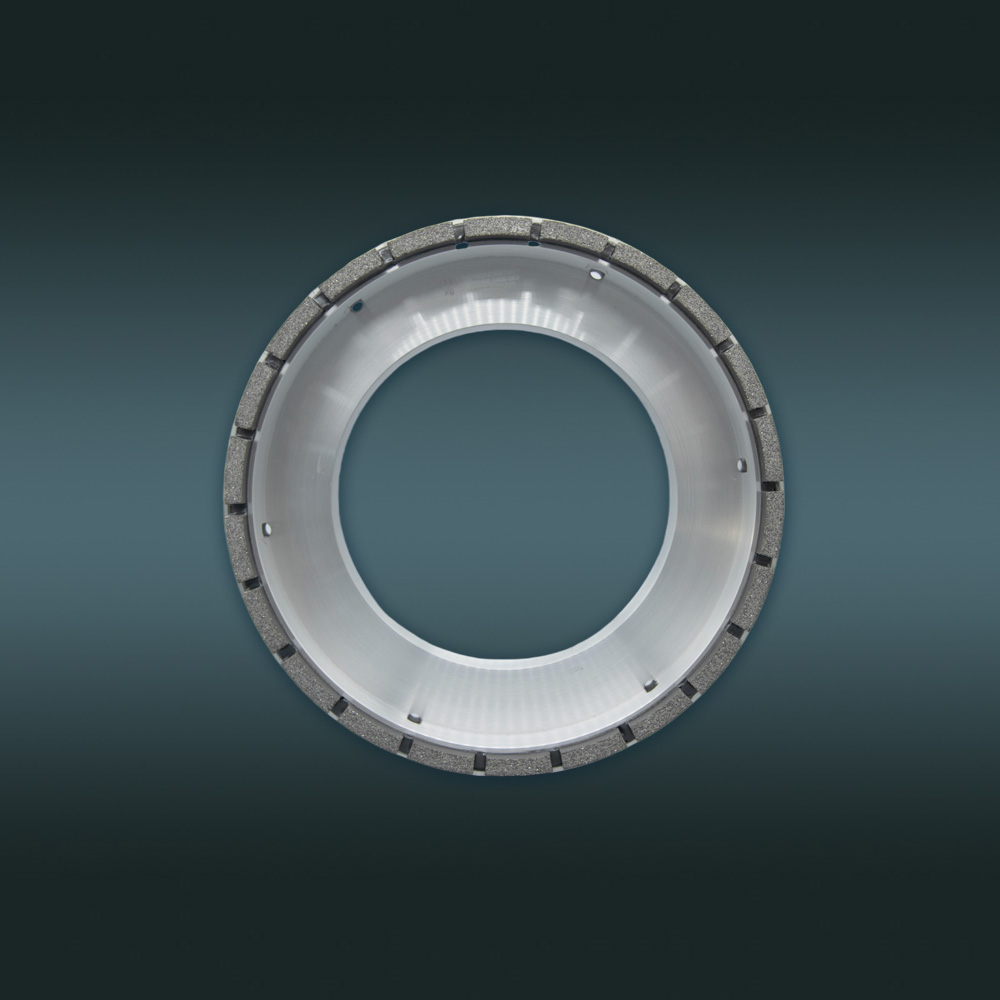

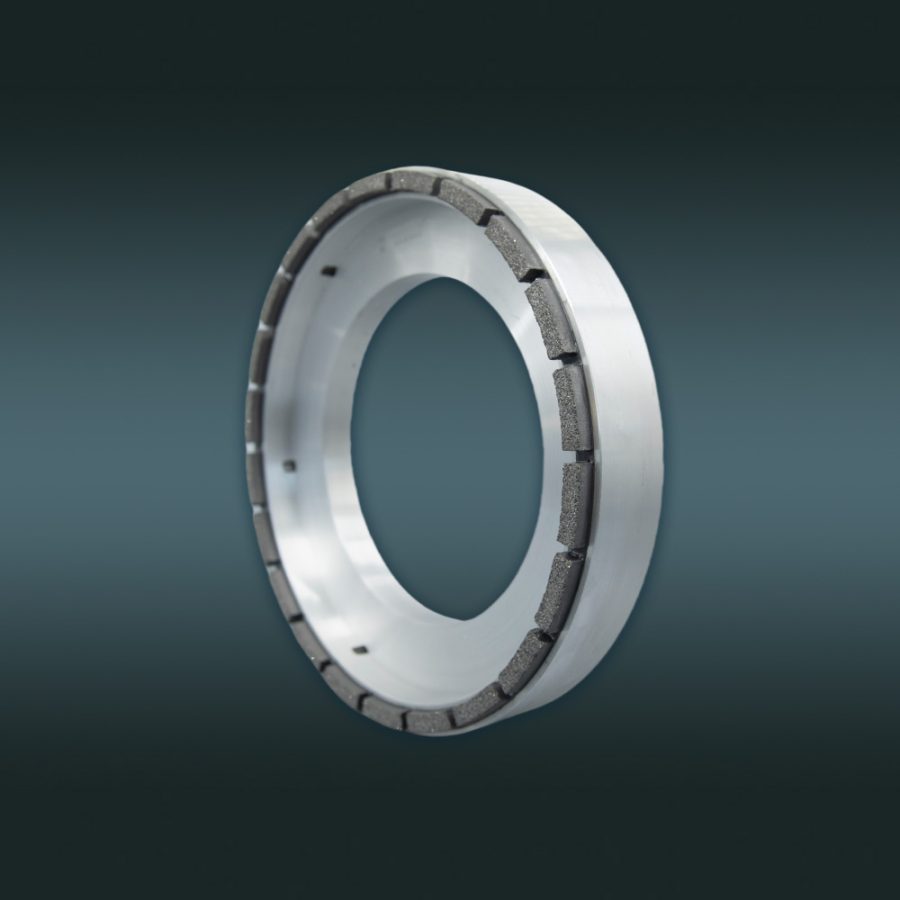

5A2H Vitrified CBN Grinding Wheel

-

Specially suitable for grinding quenched steel, alloy steel, stainless steel and other materials.

High hardness, good wear resistance, high processing efficiency, good heat resistance and chemical stability.

Minimum Order Quantity: 10pcs

Net Weight: 6KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

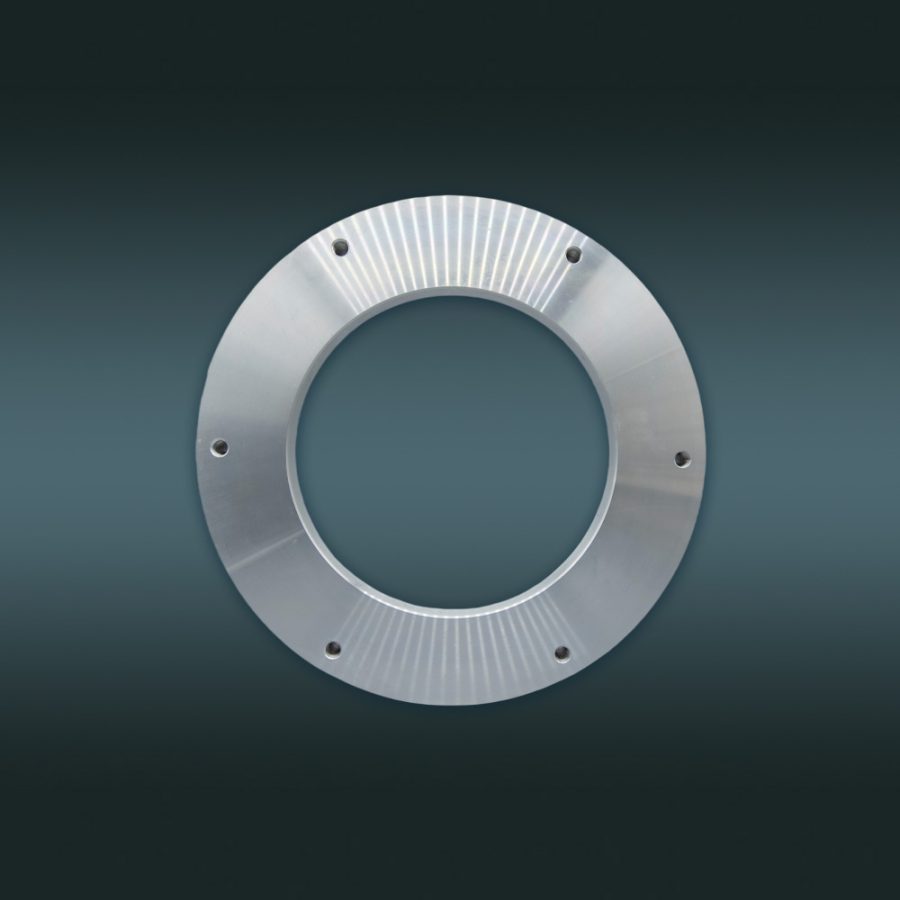

Detail

Description

5A2H vitrified CBN grinding wheel is a high-performance grinding tool, with CBN abrasive hardness second only to diamond. Combined with ceramic binder, the grinding wheel has excellent wear resistance. When grinding temperature sensitive materials such as quenched steel, it is less likely to cause chip sticking. And it is not prone to chemical reactions with iron group elements, making it particularly suitable for processing various alloy steels, stainless steels, and other materials.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | CBN |

| Bond | Vitrified bond |

| Abrasive Grit Size | 80/100 |

| Model Number | 5A2H |

| Specification | 600*32*260*170*6.5 |

| Outside Diameter | 600mm |

| Hole | 260mm |

| Total Thickness | 32mm |

| Net Weight | 6KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding special high-speed steel cutting tools such as tungsten and tungsten molybdenum high-speed steel, vanadium alloy steel, cobalt alloy steel, as well as honing other steel quenching tools

- Used for grinding magnetic materials such as soft magnetic ferrite.

- Suitable for grinding of hard alloy products such as cemented carbide.

- Used for grinding various parts made of heat-resistant steel and high hardness alloy steel.

Competitive Advantage

- High hardness, good wear resistance, and high processing efficiency.

- Good heat resistance and chemical stability, making it less prone to chip sticking when grinding temperature sensitive materials such as quenched steel. And it is not prone to chemical reactions with iron group elements, making it suitable for processing various alloy steels, stainless steels, and other materials.

- Good grinding performance, reducing defects such as workpiece burns and cracks.