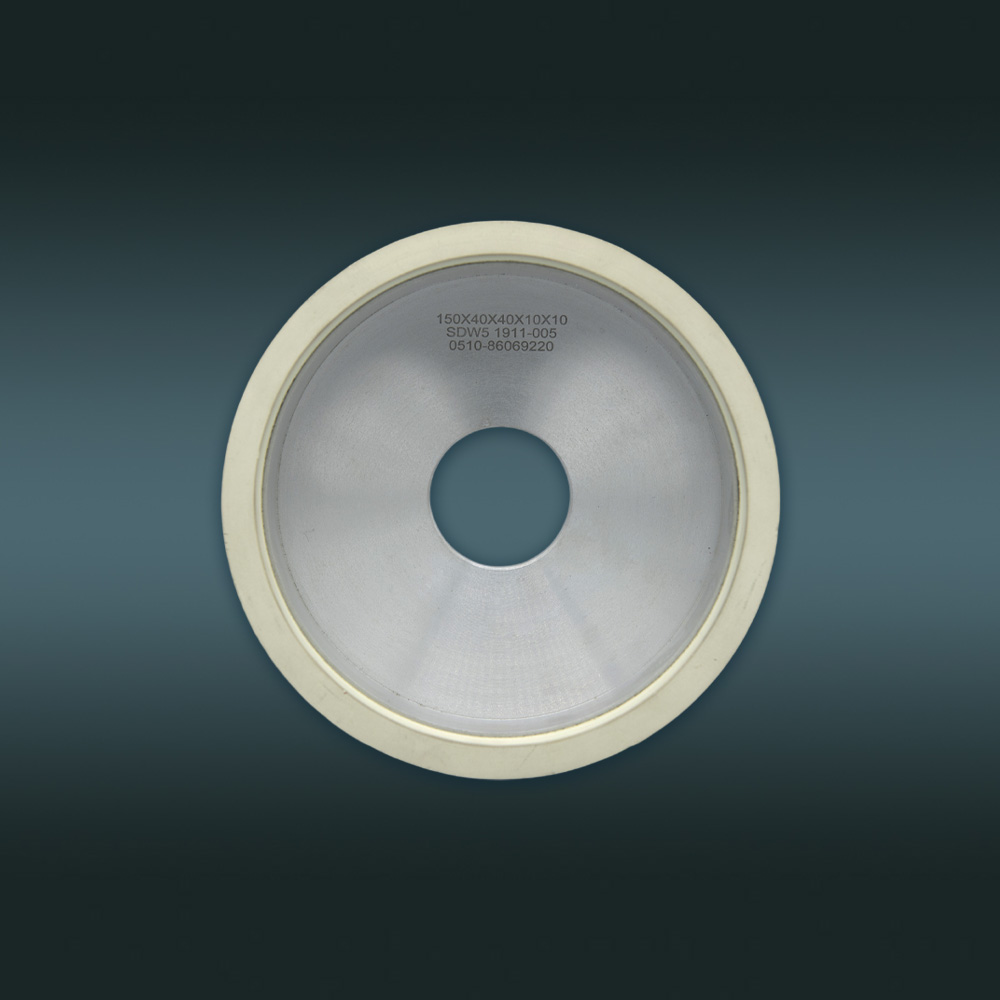

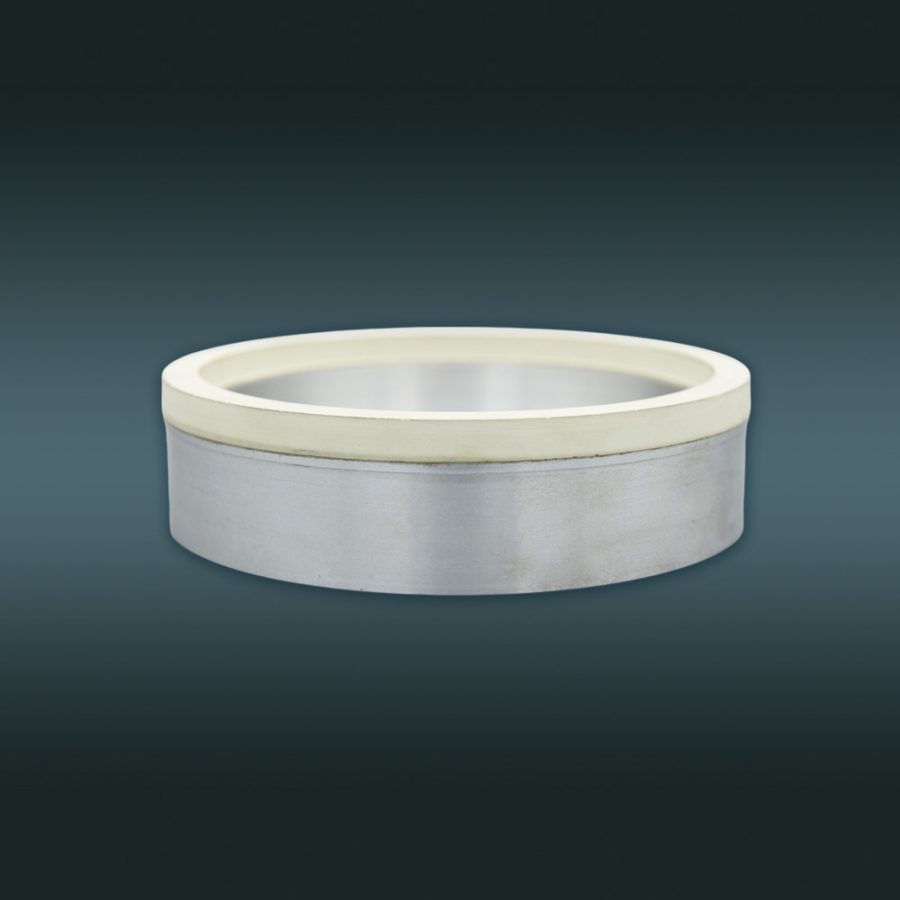

5A2 Vitrified Diamond Grinding Wheel

-

Used for grinding and grinding cutting tools such as PCD, CVD, PCBN, hard alloys, metals, stones, glass, ceramics, etc.

Good heat resistance, corrosion resistance, high hardness, high grinding efficiency, high precision, and long service life.

Minimum Order Quantity: 30pcs

Net Weight: 430g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

The 5A2 Vitrified Diamond Grinding Wheel is an important tool mainly used for grinding and grinding PCD and PCBN superhard cutting tools, as well as for processing hard and brittle materials such as hard alloys, ceramics, gemstones, and crystals.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | W5 |

| Model Number | 5A2 |

| Specification | 150*40*40*10*10 |

| Outside Diameter | 150mm |

| Hole | 40mm |

| Total Thickness | 40mm |

| Net Weight | 430g |

| Minimum Order Quantity | 30pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding superhard cutting tools such as PCD and PCBN.

- Grind and trim V-CUT knives, PDC composite cutting tools, etc.

- Grinding hard alloys and tungsten steel to achieve high-precision and high-efficiency processing.

- Processing ceramic materials to reduce material cracking, ensure processing accuracy and surface smoothness.

- Used for cutting and grinding precious materials such as gemstones and crystals.

- Used for grinding semiconductor silicon wafers and solar silicon wafers.

- Grinding processing of magnetic materials such as rare earth materials.

Competitive Advantage

- Good heat resistance and corrosion resistance, able to work stably for a long time under harsh working conditions such as high speed, high temperature, and high pressure.

- High hardness, capable of grinding hard alloys, ceramics, optical glass and other high hardness materials.

- High grinding efficiency, high precision, more wear-resistant, and long service life.

- Good environmental friendliness, less likely to generate large amounts of dust and waste, and less pollution to the environment.