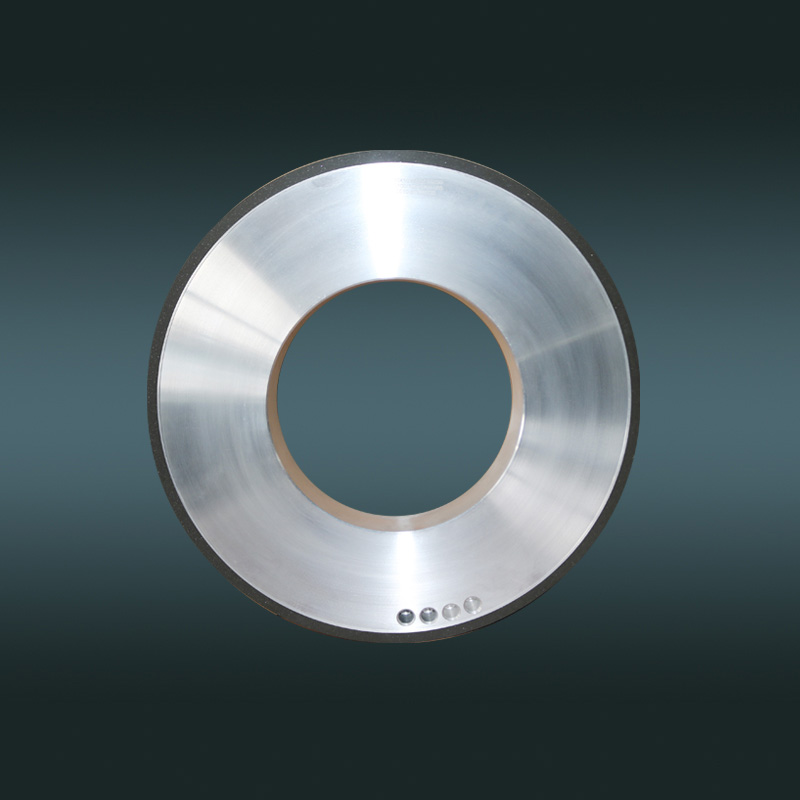

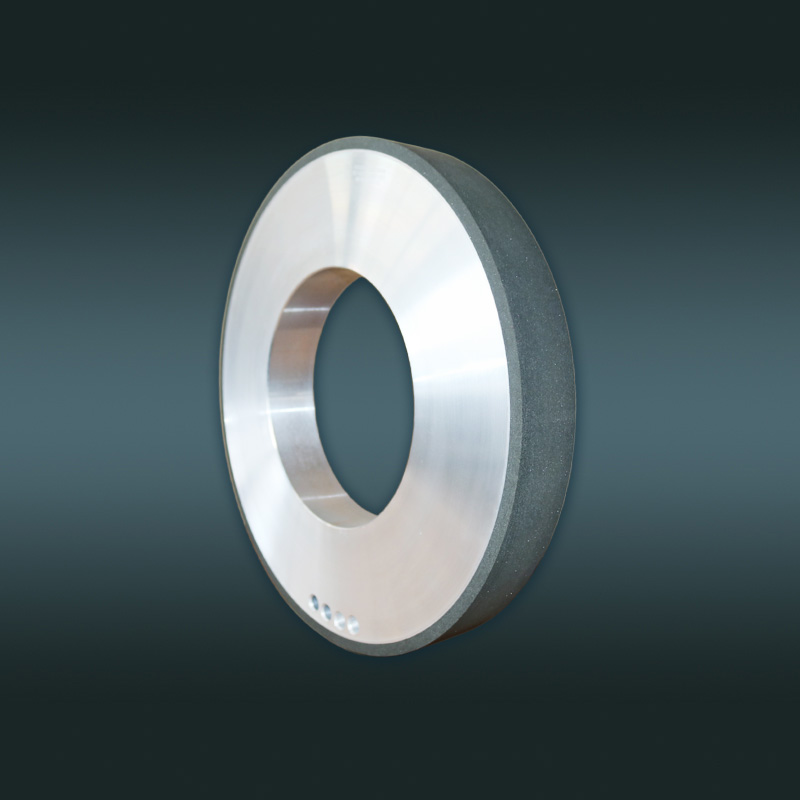

Resin Diamond Parallel Grinding Wheel for NdFeB magnets

-

Used for forming, grooving, cutting, and chamfering processes of NdFeB magnets. High efficiency, high precision, and less prone to clogging and burns.

Minimum Order Quantity: 10pcs

Net Weight: 13KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

The 400mm outer diameter resin diamond parallel grinding wheel is the core tool for achieving efficient and high-precision machining in the NdFeB industry. It is specifically designed for processes such as forming, grooving, cutting, and chamfering of sintered NdFeB materials.

Specifications

| Place of Origin | China |

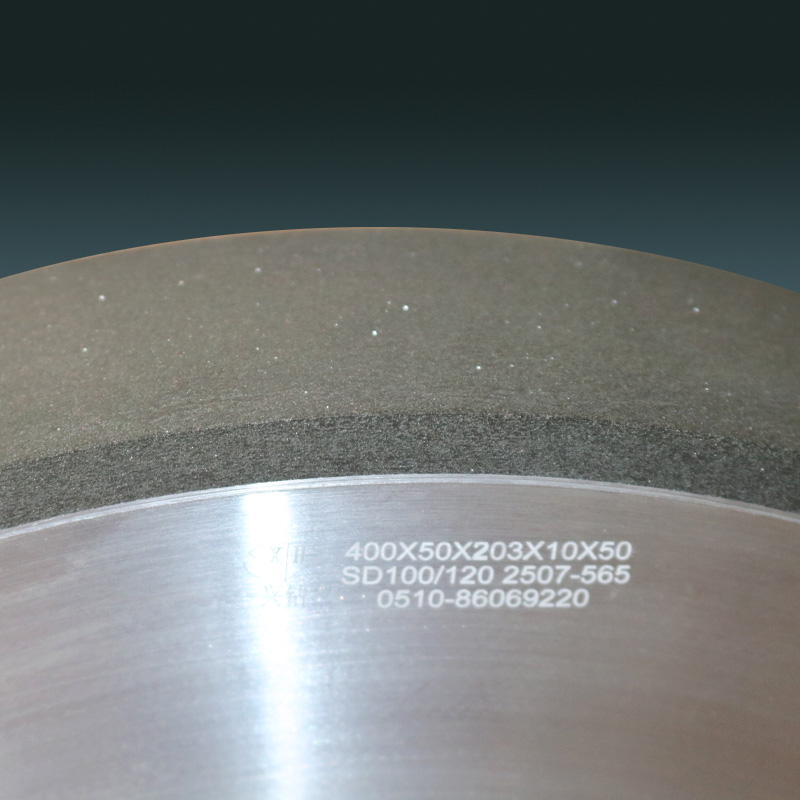

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Resin bond |

| Abrasive Grit Size | 100# |

| Model Number | 1A1 |

| Specification | 400*50*203*10*50 |

| Net Weight | 13KG |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for surface grinding, grinding sintered NdFeB blocks to a specified thickness and flatness.

- Used for double-end grinding, simultaneously grinding two parallel planes of a workpiece in a single operation with extremely high efficiency.

- Used for grooving/slicing, grooving or slicing magnets.

- Used for cylindrical grinding, grinding the outer diameter of cylindrical magnets.

Competitive Advantage

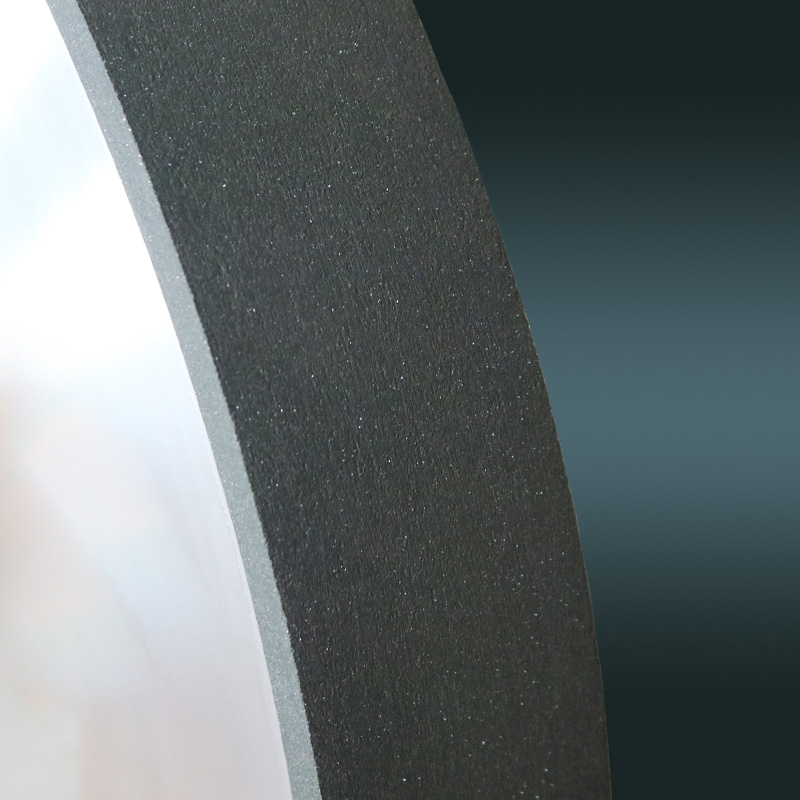

- High processing efficiency: The sharp diamond abrasive grains enable rapid material removal, improving production efficiency.

- High processing precision: Ensures accurate dimensional tolerances and good shape accuracy (such as flatness and parallelism) for workpieces.

- Good surface quality: The elastic buffering effect of the resin binder results in low surface roughness (low Ra value), reducing subsequent polishing work.

- Long lifespan: Compared to silicon carbide grinding wheels, diamond grinding wheels have a lifespan dozens of times longer, reducing the frequency of wheel replacement.

- Resistant to clogging and burning: Excellent heat dissipation effectively prevents materials from being "burned" due to overheating (leading to a decrease in magnetic properties).