The Benefits of Electroplating Technology for Customized Grinding Solutions

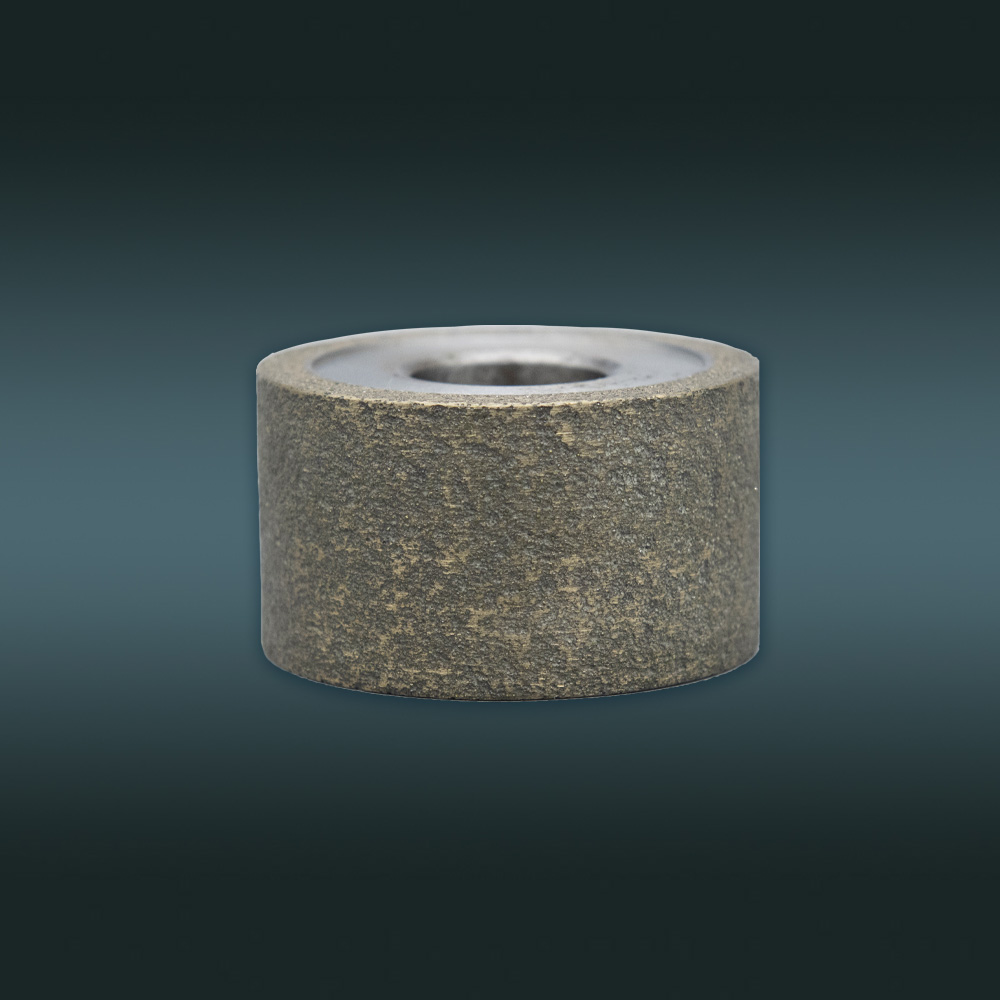

Electroplating technology has become one of the most effective manufacturing methods for producing high-performance diamond and CBN grinding tools. In modern precision industries, where accuracy, efficiency, and consistency are essential, electroplated grinding solutions offer significant advantages. This technology allows abrasive grains to be firmly bonded to the tool surface through a controlled electrochemical process, creating grinding tools that deliver outstanding cutting performance and dimensional stability. One of the key benefits of electroplating technology is its ability to provide highly precise abrasive placement. Unlike traditional bonding methods, electroplating ensures that diamond or CBN grains are evenly distributed and securely fixed in a single layer. This precise grain exposure allows each abrasive particle to work efficiently, resulting in sharper cutting action, reduced friction, and improved grinding accuracy. Such precision is especially important in industries requiring tight tolerances and fine surface finishes.

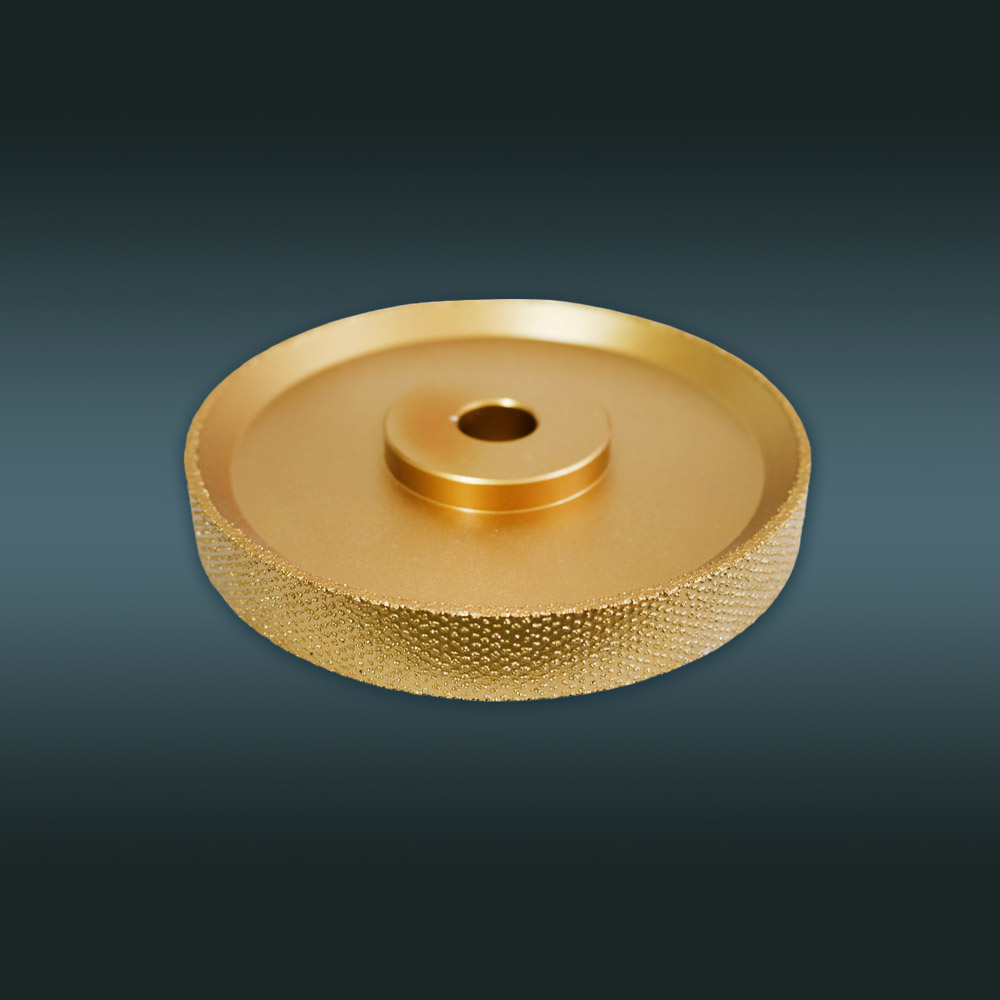

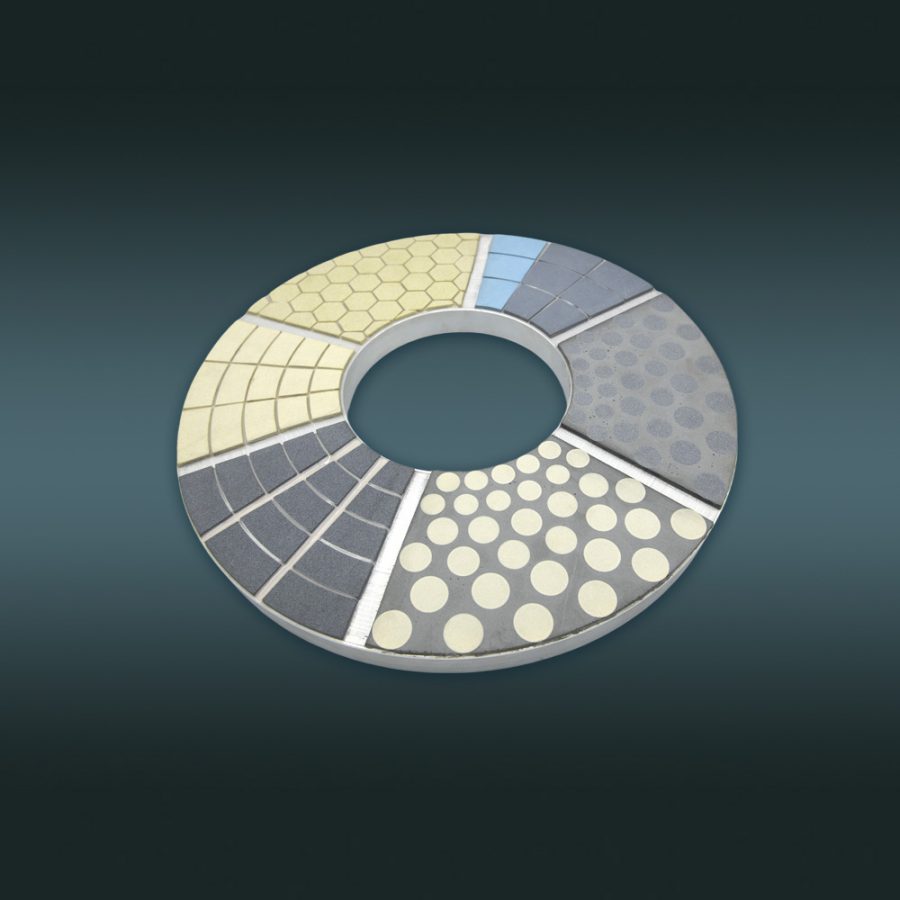

Electroplated grinding tools are particularly well suited for customized solutions. The electroplating process allows manufacturers to design tools in various shapes, sizes, and profiles according to specific customer requirements. Whether it is a complex contour, special groove, or non-standard dimension, electroplating technology makes it possible to produce tailored grinding tools that perfectly match unique machining needs. This flexibility makes electroplated tools ideal for specialized and high-value applications. Another significant advantage of electroplating technology is its superior grinding efficiency. Because the abrasive grains are firmly exposed on the tool surface, electroplated wheels provide aggressive cutting performance from the very first use. This leads to faster material removal rates and shorter processing times, helping manufacturers improve productivity and reduce operational costs. In high-volume or high-precision production environments, this efficiency offers a clear competitive advantage.

Electroplated grinding tools also offer excellent shape retention during operation. Since the abrasive layer is securely bonded to the tool body, the wheel maintains its original geometry throughout its service life. This ensures consistent grinding results and minimizes dimensional deviations. For applications such as mold manufacturing, medical device processing, and optical component production, stable tool shape is essential to achieving reliable and repeatable outcomes. Heat control is another important benefit of electroplated grinding solutions. The single-layer abrasive structure allows better chip removal and heat dissipation during grinding. Reduced heat buildup helps protect both the workpiece and the grinding tool, minimizing thermal damage, surface burns, and micro-cracks. This is particularly valuable when working with heat-sensitive materials or high-hardness alloys.

From a quality perspective, electroplating technology contributes to excellent surface finishes. The uniform abrasive exposure ensures smooth and controlled material removal, resulting in clean surfaces with minimal defects. This makes electroplated grinding tools suitable for applications requiring fine finishes, such as semiconductor components, precision ceramics, and diamond jewelry processing. Electroplated grinding tools also support cost-effective customization. While fully customized tools may traditionally involve high production costs, electroplating allows efficient small-batch or specialized production without compromising quality. This enables manufacturers to meet specific customer demands without excessive investment, making customized grinding solutions more accessible and economical.

Durability and reliability further enhance the value of electroplated grinding tools. The strong bonding between abrasive grains and the tool body ensures stable performance under demanding working conditions. With proper application, electroplated tools deliver consistent results throughout their service life, reducing tool replacement frequency and production interruptions. In conclusion, electroplating technology offers a powerful combination of precision, flexibility, efficiency, and reliability for customized grinding solutions. By enabling accurate abrasive placement, superior cutting performance, excellent shape retention, and cost-effective customization, electroplated grinding tools meet the evolving needs of modern precision industries. As manufacturing requirements continue to become more specialized, electroplating technology will remain a key driver in delivering high-quality, tailored grinding solutions.